INRTU manufactures high-performance drone parts from composites

Research staff and students of the Institute of Aviation Mechanical Engineering and Transport have produced parts for drones using composite materials. The technical development is managed within the strategic project i.DIT under the Priority 2030 Program.

According to Yuriy Ivanov, head of the research laboratory ‘Digital Technologies for the Production of Products from Polymer Composite Materials’ the Institute was previously engaged in the mechanical processing of composite materials for the aviation industry. Currently, the engineers develop the actual direction, the production of structures from composites.

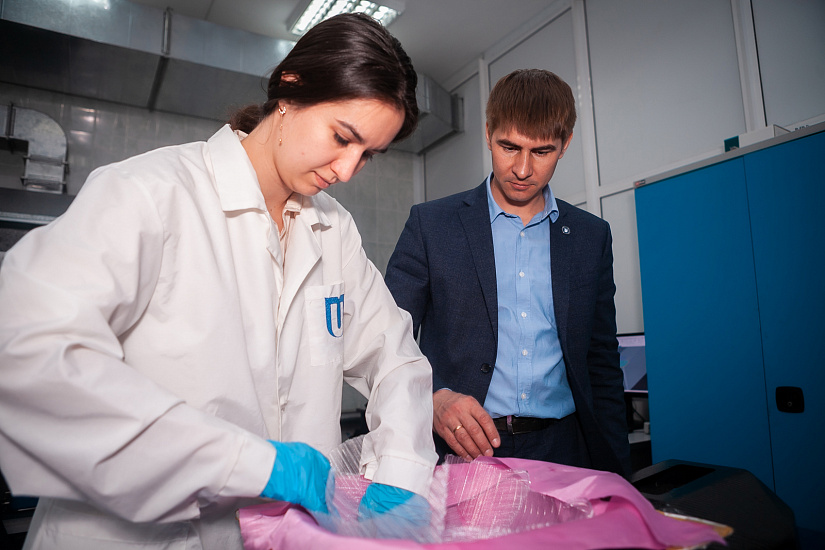

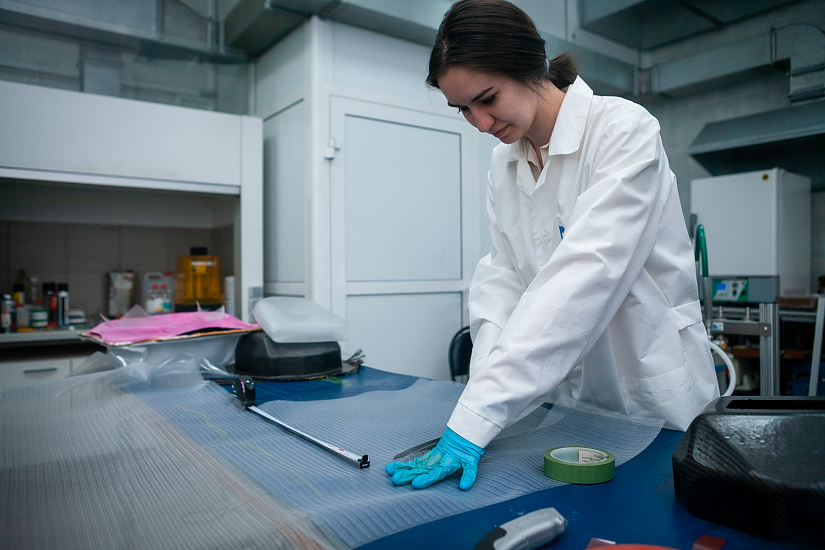

“Within the strategic project i.GeoDesign the Siberian School of Geosciences (SSG) uses drones to carry for complex research. Previously, parts, including protective covers, were made from composite by manual molding methods, yielding rather heavy parts. With a team of 4th-year students, we decided to create a prototype of a lightweight, durable and aesthetic protective cover. It resulted in a reduction in weight of the part from 250 grams to 105 grams. Colleagues appreciated our development and ordered a small series of 10 parts,” the head of the laboratory said.The team led by Yury Ivanov includes Marina Lebedeva, enrolled at the university in 2019 by target program of Irkutsk Aircraft Plant, a branch of Irkut Corporation. During her third year, the future design engineer worked on a project to engineer a lightweight, non-corrosive fuel tank from composites. This development in the interest of the aircraft plant was successfully completed and Marina decided to continue her research on this subject joining the team producing drone hulls.

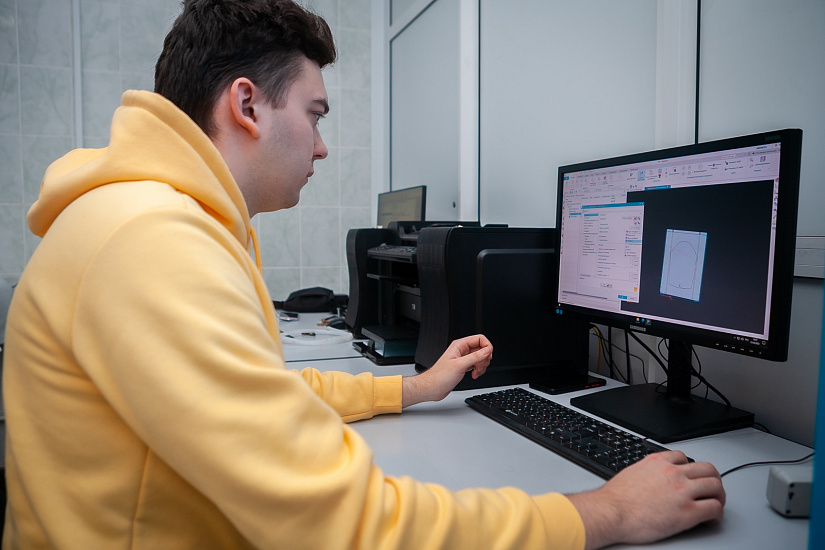

"After obtaining the dimensions of the protective cover for the drone, I designed a 3D model of the fitting in Siemens NX. For this design the challenge was to achieve very thin walls and to meet the weight requirements of the part. Moreover, the design was to be adapted to the equipment available in the university's laboratory, thus ensuring technological adaptability to the production process.The fiberglass matrix will be repeatedly used," said Marina Lebedeva.

Marina will present the results of her research as her diploma project (supervisor - associate professor Albina Rodygina). The graduate is planning to gain additional skills for the production of tooling and composite parts in the magistracy.

Photos by Arseny Chekmariov