INRTU and MedTechService strengthen cooperation

A delegation from INRTU, headed by Rector Mikhail Korniakov, visited MedTechService. The students from Technical University got acquainted with the full production cycle of diabetic test strips and discussed with the company's management the prospects for further cooperation.

As Mikhail Korniakov points out, INRTU and MedTechService have a long-standing partnership. The first cooperation agreement was signed in February 2018, this document defined the vector of interaction in the research sphere. In March of this year, the university and the company signed an agreement on personnel training. The university is interested in the company's participation in the project activities of students and in the targeted training of students.

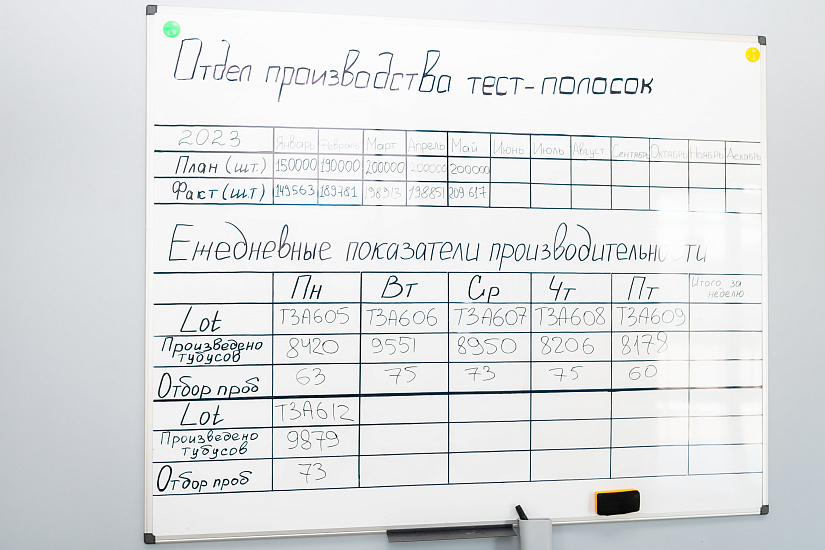

Fedor Zheleznyakov, founder of MedTechService LLC, conducted the tour for Polytechnic students. He knows firsthand what diabetes is. People with this disease have a special way of life, the quality of which is determined by self-monitoring of blood glucose levels. That is why Fyodor Petrovich proposed to build the first in Russia enterprise of full cycle of production of diabetic test strips and glucose meters. This is how a factory appeared in Irkutsk with a wide range of technological and scientific competences in the sphere of blood glucose control. The project was supported by investors and the Irkutsk Region Development Corporation. The company's products are supplied to 40 regions of Russia and CIS countries.

"Together with our partners from the Republic of Korea, we have developed and implemented a unique technology that uses the latest developments in electronics, the latest generation of enzymes, and polymer-carbonic paste for the base of the enzyme electrode. High-tech production puts our products among the best in the world in terms of accuracy and stability of measurement results. I would like to point out that only five countries know how to make diabetic test strips.

Production process at the factory is automated, the equipment was made in Korea to our order. The laboratory is equipped with an analyzer with reference accuracy. Humidity modes allow for long-term storage of test strips," said Fedor Zheleznyakov.

Employees of INRTU got an idea of the production process, which includes application of enzyme, drying in the oven, and cutting. After passing quality control and getting a stamp of marketable products, the test strips go to the packaging line.

Fedor Zheleznyakov focused his attention on the quality of products, which is ensured by a highly professional team:

"The plant has 15 quality boundaries, from receiving raw materials to the output of packaged products. Our partners in Korea register 15% defects, ours - 3%. Today we definitely know more, we know how to organize all the processes correctly and produce excellent products. Our employees work no worse than the Japanese, Koreans or Germans. We are grateful to INRTU for the support at the beginning of our work, when the team was just being formed. Now there are 10 polytechnics working at the plant. All of them show good training to cope with production tasks.The second founder of the company, Sergey Dyachenko, is a graduate of INRTU. He graduated from the university in 1981 as a road construction engineer.

"At the stage of launching production, we needed people with a technical background, and the Irkutsk Technical University was very helpful in this respect. We have improved the Korean technology and won two grants.

The company is constantly working to improve product characteristics and optimize production. The enzyme improvement process is continuous, so joint R&D work is important.

The university has many specialties that we are interested in. First of all, we need specialists in microbiology, biotechnology, microelectronics, and automated systems management.

Currently, production is expanding, and the question of organizing a second shift arose. We are ready to conduct production practices and take a closer look at promising students," said Sergey Dyachenko.

The plant now employs 77 people, and the average age is 25. The company has created a comfortable climate for young people, and there are prospects for career growth. Each employee undergoes an internal audit once every three months.

Alexander Yakimov, a graduate of the INRTU chemistry and metallurgy department, started as a foreman of the test strip production area and then, based on the audit results, he was appointed head of the packaging department. Alexander's experience in organizing, which he gained in the student trade union committee of the University, helps him in production.

"I graduated with a bachelor's degree and a master's degree from INRTU (2019). I remember with gratitude my teachers Antsiferov Evgenii Aleksandrovich and Bozhenkov Georgii Viktorovich. The university organizes good industrial practices. University of Technology for me is not only knowledge, but also friends, with whom I keep in touch.

I found out about the opportunity to get a job at the MedTechService plant at INRTU. I had an interview, I liked the production. The plant provides professional growth, we constantly improve our qualifications. There is a young management, young employees. We are all on the same wavelength," Alexander Yakimov shared his impressions of his work.

The INRTU delegation was shown the work of the mobile application, which synchronizes with the glucometer and allows to keep diabetes under control. The company also works with the digital platform "Personal Medical Assistants", which was launched in the Irkutsk region as part of a pilot project of the Ministry of Health of Russia on remote monitoring of patients' health using high-tech devices and services.

Discussing the formats of interaction, Rector Mikhail Korniakov noted that all 3rd year students have one day dedicated to project activities:

"Companies can upload their cases on current production topics. To effectively solve projects, students from different disciplines are enrolled in teams. The companies' employees, who act as mentors, identify the most talented students in the process and invite them for internships and jobs."

The leaders of MedTechService supported this initiative and were also interested in becoming mentors for students in the "PROentrepreneurship" program, which is overseen by INRTU's Youth Policy Department.