Gravity Concentrator presented by ServiceTechnoProm, a company founded by INRTU graduates

ServiceTechnoProm Company, Shelekhov town, established by 2011 alumni of the Automation and Control Department, presented a domestic gravity concentrator for processing mineral and technogenic raw materials. The advantages of the gravity equipment were highly recognized by Rector Mikhail Korniakov and the university staff.

Since 2015 ServiceTechnoProm has been supplying equipment, components and spare parts to the mining and processing companies. Cooperation is organized with the Russian and global gold mining leaders, such as Polyus, Highland Gold, Zapadnaya Gold Mining, etc.

According to Nikita Kiselev, CEO, Canada and the European Union supplied gravity concentrators to Russia for three decades. The implementation of the import substitution initiative in 2022 encouraged the engineers to apply their experience in designing systems and devices. For production, ServiceTechnoProm collaborated with teams among them Usolmash, and INRTU employees.

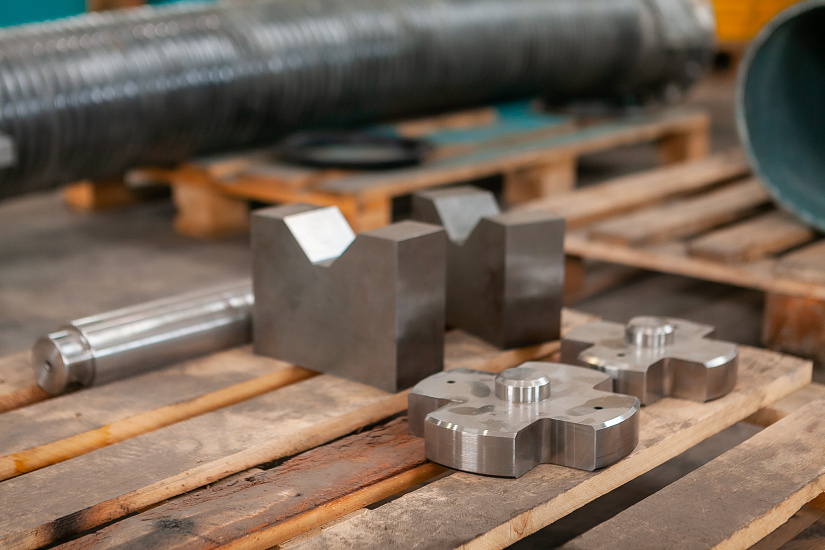

"The Design and Technology department of the university, headed by Anton Shutenkov, helped us in preparing the design documentation. The INRTU team also performs incoming and outgoing inspection, as well as quality control of parts. Bench tests are currently underway, and in the near future, the gravity concentrator will be delivered to the gold extraction plant. After confirming the quality of the equipment in industrial conditions, we plan to produce up to 12 units per year," said Nikita Kiselev.Alexander Burdonov, Associate Professor at the Department of Concentration of Minerals and Environmental Protection named after S. B. Leonov, said that the development is based on the results of scientific research jointly conducted with the university.

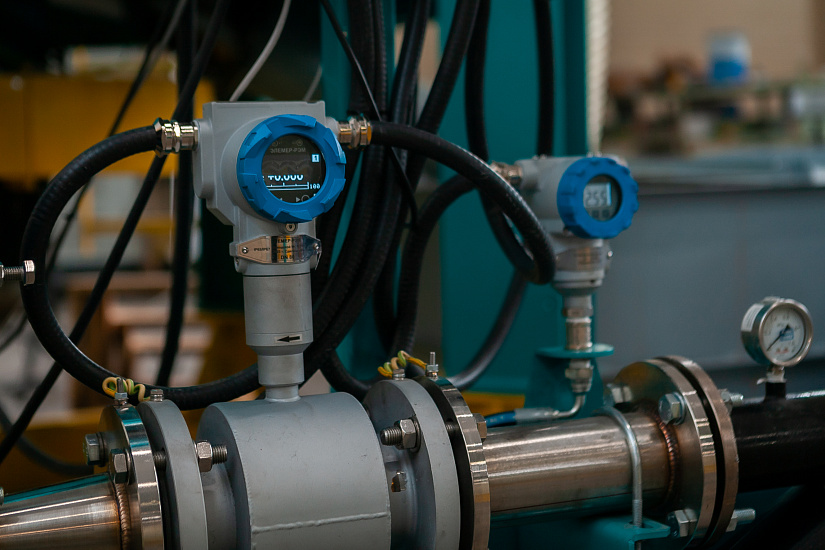

“Since 2018 the employees of our department and ServiceTechnoProm, have published six scientific articles in Russian and foreign journals indexed in the Scopus database. Now in print is a work for a highly ranked publication (Q1). Working jointly with ServiceTechnoProm, we modeled flows in the concentrator body, and recorded changes on different technological parameters. The tests were performed on a laboratory unit, using computer software to analyze the working mechanism of an industrial concentrator. We have recently filed an application for patent. This project is significant because the graduates work with INRTU and are interested in further cooperation. We plan to implement new projects in the mining and processing industry," said Alexander Burdonov.Vladislav Pelikh, Development Director of ServiceTechnoProm, demonstrated the principle of the gravity concentrator. The free fine particles containing mineral components are extracted by separation in the loosened layer. Fluidization occurs when water is fed into the concentrating rings through the holes against the action of centrifugal force.

According to Vladislav Pelikh, gravity concentrators are capable of solving various production tasks, including iron removal from minerals, extraction of platinum, silver, mercury and copper, sand pretreatment, etc.

Photos by Arseny Chekmariov