INRTU Opens Flotation and Reagents Laboratory

Department of Mineral Processing and Environmental Protection named after S.B. Leonov opened the laboratory of flotation and reagents. The research unit is equipped with analytical instruments for fundamental, applied research and creating technologies that contribute to efficient ore dressing. The cost of the equipment purchased under the Priority 2030 Program was RUB 4 million.

The laboratory is headed by Associate Professor Alexander Burdonov. The goal of the team is to conduct research in chemistry, automation and materials science for the needs of mining and processing plants. The scientific goals are combined into the project "Digital and Production Solutions in Mineral Processing" implemented within the iDIT strategic project of the Priority 2030 Program. The consortium includes the Irkutsk Institute of Chemistry named after A.E. Favorsky of the Siberian Branch of the Russian Academy of Sciences, TOMS Research and Development Institute, Irkutsk Heavy Machinery Plant and Skoltech.

The laboratory mathematically models technological processes, creates units for studying mineral and technogenic raw materials, designs unique equipment for metallurgical enterprises, including the line of the domestic flotation machines. It is panned to run a working unit comparable to foreign analogues in terms of quality and capacity; foam control in the beneficiation process will be carried out using artificial intelligence.

According to Alexander Burdonov, cooperation with the Irkutsk Institute of Chemistry (Siberian Branch of the Russian Academy) is done on a permanent basis. The Institute synthesizes and provides the university with reagents to evaluate their flotation activity when interacting with sulfide minerals. More than 20 reagents have already been tested, two of which were obtained for the first time. In 2023 the team published four scientific articles indexed in the international Scopus database.

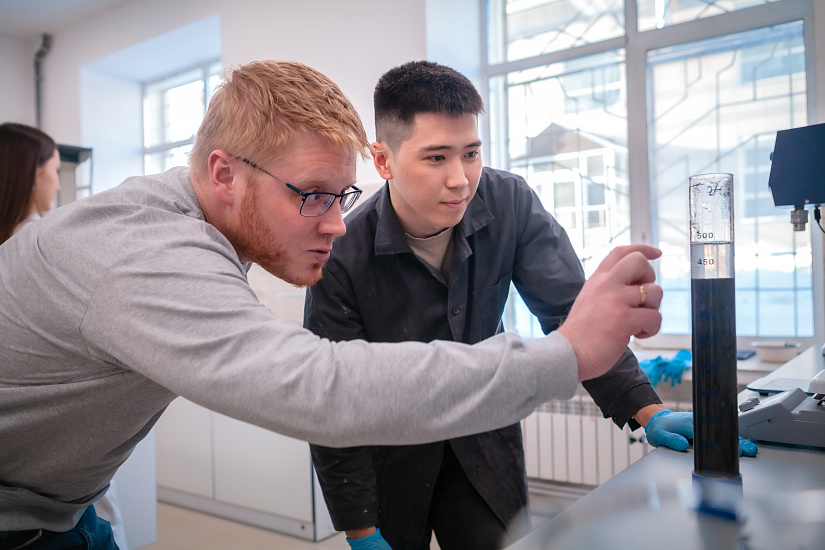

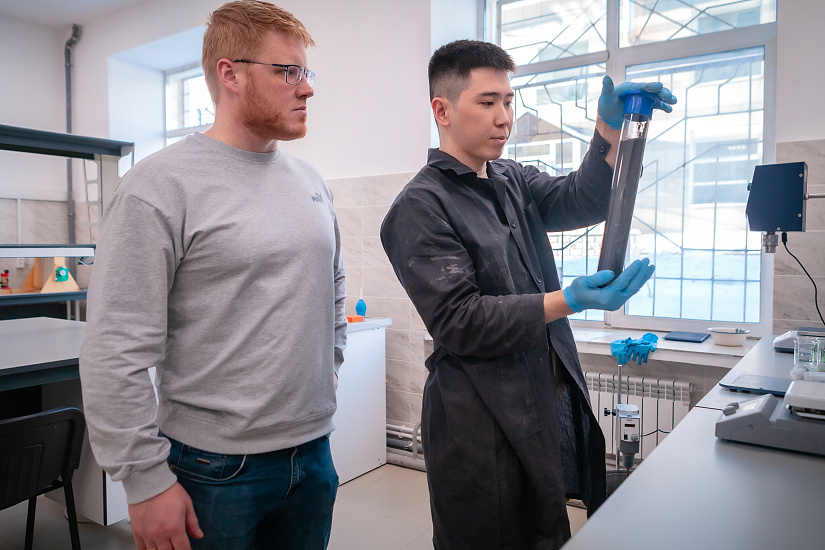

"Currently, PhD students are working in the Flotation and Reagents Laboratory. With the start of the spring semester we will involve second-year bachelor students - ecologists and enrichment specialists – in the scientific work, which will allow us to significantly expand the research topics," said Alexander Burdonov.University students and staff have access to scales, agitators, plates, drying cabinets and other equipment that ensures the production of research samples with the desired particle size distribution. An automated sample splitter will help significantly save time and efficiently prepare samples for subsequent testing.

"Automation allows to separate samples weighing 150-300 kg, while obtaining the required number of samples in the shortest possible time. Increasing the volume of ore preparation is a demand of the industry and is therefore one of our priority tasks," Alexander Burdonov said.The laboratory also received a spectrophotometer and shakers for mixing chemical solutions and minerals. The results of observations will allow to determine the sorption properties of synthesized reagents at a given temperature, which is controlled by a thermal chamber.

Equipment for slurry thickening and water treatment is installed in the research division. INRTU technologies of dilution and flocculants dosage and optimal pH selection will be in demand at mining and processing plants seeking to set up closed-loop water systems.

Technological tests are also performed on the previously purchased flotation machine and gravity concentrator to recover gold and non-ferrous metals.

"The gravity concentrator was created by ServiceTechnoProm company with the participation of Irkutsk National Research Technical University. The gravity separation device is in demand at mining and processing enterprises. The next stage is to design the largest concentrator in Russia with high productivity," said Alexander BurdonovThe benefits of the new equipment have already been appreciated by 1st year PhD student Tatyana Sakhabutdinova. She is focused on studying the flotation activity of reagents capable of extracting the maximum amount of gold from hard-to-enrich ores.

"For many experiments we need a flotation machine, a spectrophotometer and a pH-meter. We use them to test the reagents in a narrower format, namely in a specific medium. This approach is caused by the fact that flotation is a labor-intensive and multi-stage technological process," said Tatyana Sakhabutdinova.

The staff of the Department of Mineral Processing and Environmental Protection named after S.B. Leonov expresses their gratitude to the TOMS Research and Development Institute represented by General Director Arkady Senchenko for financial assistance in the renovation of the laboratory.

Photos by Arseniy Chekmaryov