Delegation of KnAAPO visited INRTU

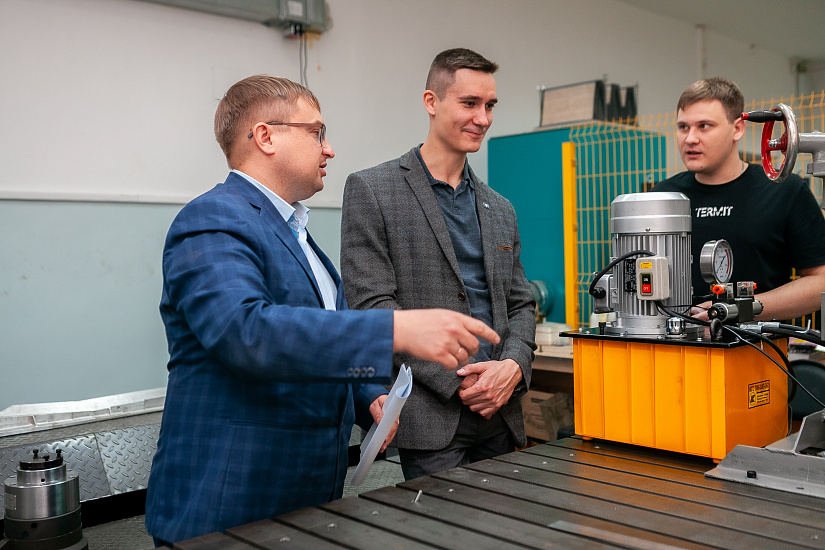

The delegation of Komsomolsk-on-Amur Aircraft Plant named after Y.A. Gagarin (KnAAPO, a branch of UAC) visited INRTU. The parties conducted experiments and approved directions for further work in the field of aircraft engineering.

Alexander Makaruk, head of the strategic project of Digital Industrial Technologies - i.DIT within Priority 2030 Program, reminded that in April the university and the UAC agreed on a roadmap for the joint work implementation. INRTU offer to partner companies import-substitution tools and technologies, and conduct tests in the labs.

The KnAAPO delegation included Roman Krupsky, Head of Scientific and Production Testing Center, Leonid Tolcheyev, Deputy Chief Technologist, Victoria Bazherianu, Engineer-Technologist, Dmitry Bobin, Head of Design Office and Alexander Golovchenko, Lead Technologist.

Roman Krupsky, Head of Scientific and Production Testing Center and a Leading Researcher, said that KnAAPO has had a positive experience working with INRTU and is ready to expand projects in the field of science-intensive aircraft building technologies.

“The first activity is similar to the work of INRTU for the Irkutsk aviation plant. This is the manufacture of a tool for processing mixed packages from various metal and composite materials. We are also interested in new repair technologies of aircraft parts made of polymer composite materials. We have brought along mixed packages and composites with imitated defects to test technologies. The most promising project is the complex ribbed parts roller straightening. The test results confirmed the high competence of INRTU staff in this area. That is why we intend to develop the terms of reference and consider the possibility to move our joint work with the university to a contractual basis,” - said Roman Krupsky.It is planned to improve the self-regulating heating tool for glue polymerization after syringing and the vacuum tool to repair mechanical defects of composite panels. After reviewing the test results, KnAAPO will decide if the project is needed. In addition, the university and the enterprise have agreed on the manufacture of lining plates for Eckold kraftformers and of an automatic-feed drill.

Photos by Arseny Chemariov