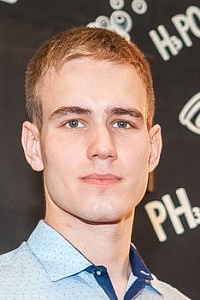

The State Examination Commission highly appreciated the startup to develop a bionic prosthetic arm developed by INRTU graduate Pavel Grigorov

The State Examination Commission highly appreciated the startup to create a bionic prosthetic arm developed by INRTU graduate Pavel Grigorov. The Polytechnic student presented a working prototype as part of the Startup as a Diploma Programme on June 20.

Pavel Grigorov has successfully completed a degree in Mechatronics and Robotics. He has been developing the startup for four years at the Aviator Design Bureau under the guidance of Alexei Govorkov, director of School of Information Technology and Data Science. Other students of the Irkutsk Polytechnic University and medics are also involved in the creation of the Prometheus Prosthesis bionic prosthesis.

The research team has been developing the presented prototype for about six months. Previously, the researchers experimented with various designs of the prosthesis.

According to Pavel Grigorov, there is a large number of innovative prostheses on the world market, but not all of them are perfect. As a rule, they cost between 300 thousand and four million rubles:

"Most companies are located abroad or in central Russia, which entails long waiting times for orders. The queue at state prosthetics workshops can take up to two years.

We have analysed these problems and formed the goal of the project - to develop an affordable and technologically advanced bionic prosthetic hand that meets the wishes of every patient".

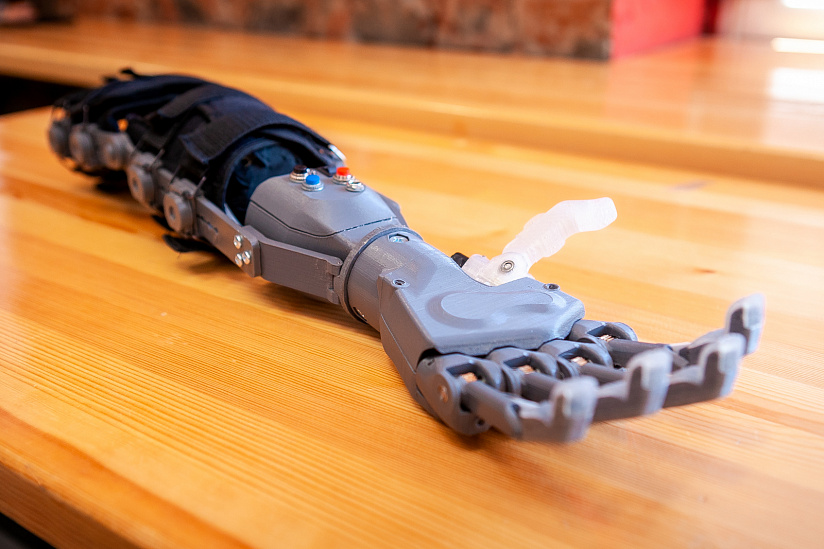

Currently, the Polytechnic's design features automatic switching between four grip positions and the ability to recognise the presence of an object in the hand. The project is aimed at people with disabilities who have lost a wrist or forearm part. The prosthesis is powered by a battery with a safety circuit board and charge control.

Most parts of the device are 3D-printed. The prosthesis is based on a mechanical hand and a residual limb socket, which is fitted with a sensor that reads the electrical signal fr om the residual limb muscles.

Pavel Grigorov explains in more detail how the artificial hand works:

"When the patient puts on the prosthesis, his stump is placed in a sleeve wh ere the skin is in tight contact with an electrokymograph sensor. When the muscles tense, the sensor sends a signal to the microcontroller, where the software decides what action to take - squeeze, unclench or change the grip. Designing a prosthesis is a complex and academic endeavour. That's because each person's residual limb muscle activity is different.

Over the course of the project, the researchers worked with two patients, on whom they tested the prototypes.

During the defence of the final qualification work, the polytechnician shared his plans for further development of the project. This summer, the research group will finalize the prosthesis in accordance with the wishes of the patient - lighten the design, manufacture parts from plastic using the additive method, making the production affordable and fast, and provide a flexible design. In addition, at the end of the summer, the innovators will apply for registration of intellectual property rights and register a legal entity.

"I would like to thank the management and teachers of Irkutsk Polytechnic for their support of student initiatives and their contribution to the development of youth potential. During my studies I met a lot of cool professionals in my field and had a bright time during my student years. Polytechnic has created all the opportunities for students to realise their potential in various fields," says Pavel.