INRTU's Diagnostic Robot Proves Its Mettle at Bratsk HPP

A diagnostic robot, developed by INRTU for En+ Group, has successfully completed trials at Bratsk HPP. The robot autonomously identifies defects, measure residual metal thickness, and evaluate weld seam quality. This technology will facilitate water conduit's condition inspections in line with Rostechnadzor regulations.

The project was launched around five years ago. Its concept originated when students took part in the En+ "Energy Laboratory" accelerator. En+ set a challenge: to create methods for inspecting turbine and embedded conduits running inside the HPP dam and its power unit sections. The developer team at INRTU was headed by Associate Professor Igor Maizel from the Department of Technology and Equipment of Machine-Building Production.

Backed by an 11-million-ruble grant from En+ Group, the developers worked on several designs, from a walking robot to a tracked prototype. After the robot's first real-condition trials in 2023 and subsequent stage-by-stage improvements, it was ready for the decisive test in Bratsk by December 2025. The on-site testing team featured INRTU's Associate Professor Igor Maizel, postgraduate student Vladimir Gilmutdinov, and En+ experts. In a four-day campaign, they managed to survey around 40 meters of the water conduit.

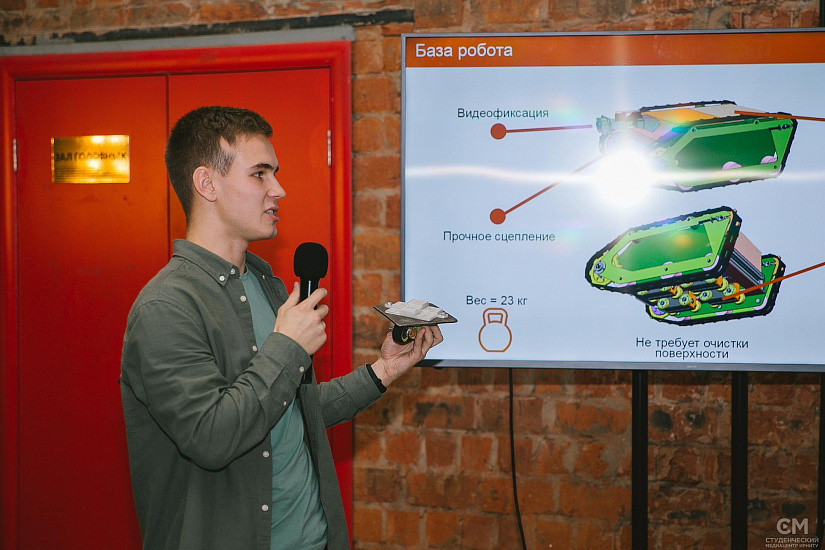

"The robot is a mobile carriage with four pairs of wheels. It is also equipped with six video cameras, a flaw detector, and a thickness gauge for taking readings. The system has proven its reliability and operational capability. While initial trials saw the robot lose grip on overhead surfaces, we solved this by increasing the magnetic adhesion force. The robot confidently moves along the entire length inside the pipe. All inspection results obtained with it have been sent to En+ specialists for interpretation," said Igor Maizel.As per technical standards, the water conduit undergoes a mandatory inspection every five years. The conventional method - erecting specialized scaffolding - is both costly and fall-risk intensive. The introduction of the diagnostic robot aims to substantially boost safety and streamline the procedure through automation.

"Over the years of work, we have created over 10 variants of the device. The final version was assembled at the Training and Research Production Center based on the university's Research and Innovation Department. Students Pavel Grigorov, Vladislav Griboedov, Alexander Piven, and Innokenty Markov participated in the robot's design. University staff handled its manufacturing and assembly. Our immediate next step is to transfer the operational prototype to the customer," emphasized Igor Maizel.Moving forward, En+ Group experts will evaluate the potential for implementing the diagnostic robot across other HPPs within the holding.

Photo credits: Igor Maizel, En+, Student Media Center