INRTU Researchers’ Development for the High-Precision Parts Production in Aircraft Manufacturing Recognized at Regional Science and Technology Competition

The research team from the Digital Design of Engineering Processes Laboratory of the Irkutsk National Research Technical University (INRTU) has become a laureate of the regional competition in the field of science and technology. The project focused on developing methods and equipment for the serial production of large-sized aircraft components and assemblies received high praise. This cutting-edge research conducted under the national Priority 2030 Program, aims to bolster Russia's aviation industry.

The project was recognized in the nomination For the Best Scientific, Research and Development, and Innovative Projects by Young Scientists.

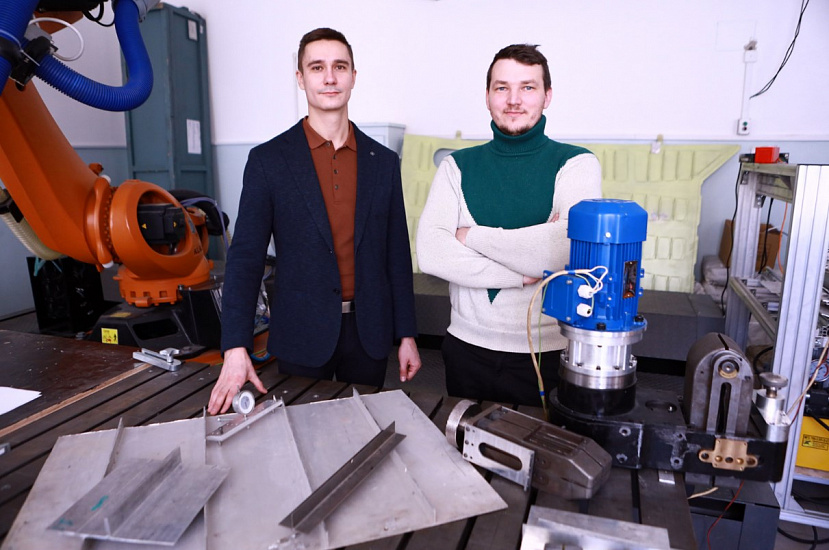

Lab head Aleksandr Pashkov, an Associate Professor of the Department of Machine-Building Production Equipment, explained that the integrated technology suite is designed to ensure exceptional quality and dimensional accuracy of manufactured parts. The core development team also included Associate Professor Oleg Samoylenko and lead programmer Sergey Faleev.

The INRTU researchers' approach involves deconstructing complex forming and straightening processes into simpler, controllable operations suitable for automation. This method boosts productivity by two to four times compared to conventional press-bending techniques.

"We are proposing a fundamentally new approach that enhances the geometric accuracy of finished components," said Aleksandr Pashkov. "Our technology maintains deviations from the theoretical contour within 0.5-0.8 mm for skin panels and 0.1-0.5 mm for structural frame parts. Moreover, it allows us to increase the fatigue life of the material after surface hardening by three times or more."He emphasized that winning the regional competition is a significant achievement and confirms the project's relevance.

"For our team, this award from the regional government is a powerful incentive to continue and expand our research, setting ever more ambitious goals," Aleksandr Pashkov added. "We are focused on replacing outdated technologies, creating and implementing digital solutions, a set of automated equipment for forming and surface deformation hardening of large-scale, low-rigidity skin and frame components for aircraft."