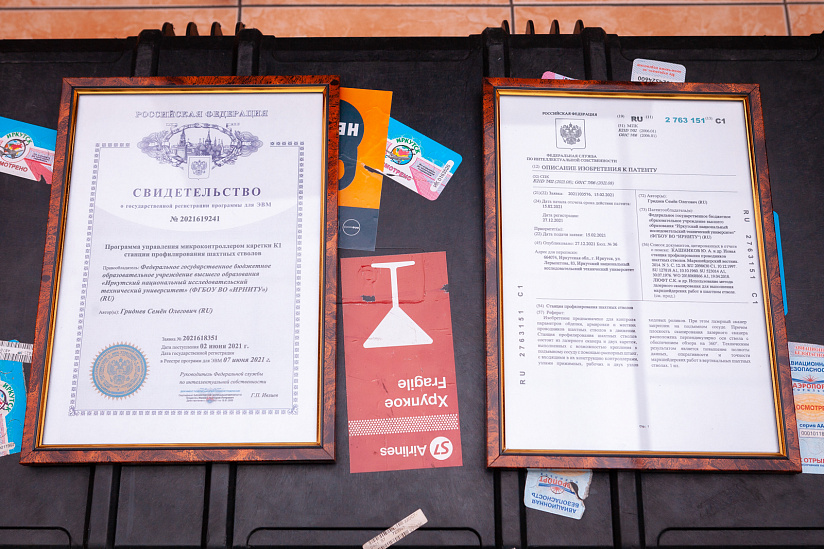

INRTU received a patent for a mine shaft profiling station developed by Semyon Gridnev

Rospatent has registered an automated profiling station for vertical mine shafts at mining enterprises.

The author of the invention is an associate professor of the Department of Surveying and Geodesy of INRTU Semyon Gridnev. The unique equipment for monitoring the parameters of rigid conductors of mine shafts in motion was called "LMS" (Laser Measuring System).

Semyon Gridnev managed to achieve a high technical result. Design solutions allow you to quickly and accurately perform surveying work in the most complex mine shafts, provide the customer with the maximum amount of information and thereby make timely decisions on which the safety and efficiency of the enterprise depends.

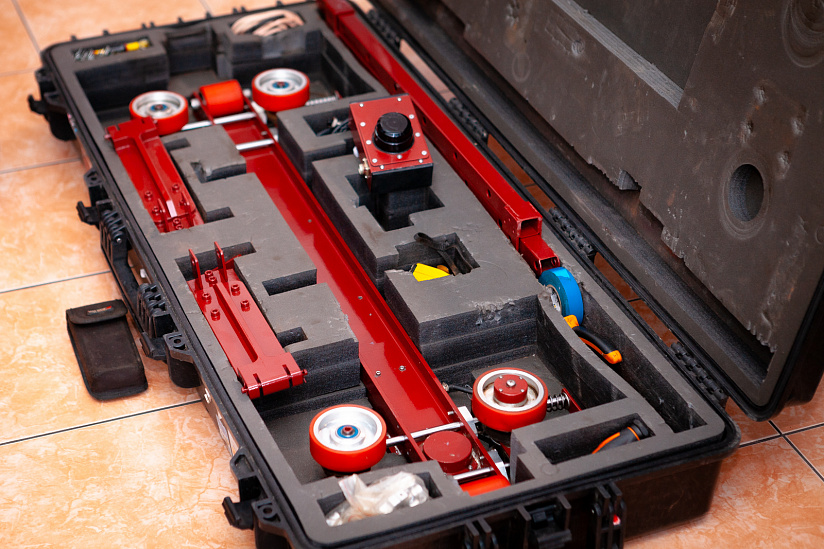

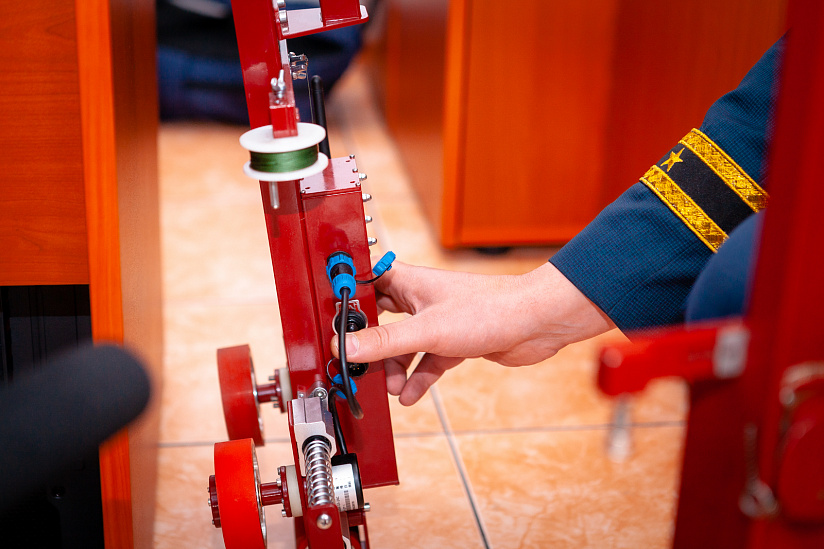

The technical novelty lies in the fact that the station consists of a laser scanner and two carriages made with the possibility of attachment to the lifting cage of the mine using spacer rods. The design also includes controllers, pressure and running roller assemblies. The laser scanner is mounted on the crate. The scanning plane is located perpendicular to the axis of the barrel with a 360-degree view.

The advantage of the station is its compactness, dust and moisture protection. The rollers are covered with polyurethane, which allows very smooth measurements. The station has no depth restrictions, runs for 10 hours on an internal battery, and is equipped with a sufficient amount of memory.

The station was highly appreciated by the specialists of the German company Thyssen Schachtbau GmbH, which is building two unique shafts with a depth of 2052 meters at the Rocky mine of the Polar Branch of PJSC MMC Norilsk Nickel (the deepest shafts in Eurasia). The surveyors of INRTU conducted profiling of a two-kilometer trunk in three hours. Meanwhile, the traditional manual profiling of 1 km takes a week, which is economically unprofitable for enterprises, since they have to stop production.