INRTU Experts Conduct Pipeline Diagnostics for Irkutsk Oil Company

Researchers at Irkutsk National Research Technical University (INRTU) are conducting expert assessments of pipelines operated by Irkutsk Oil Company (IOC). The university specialists perform complex mathematical calculations, develop 3D models, and propose effective engineering solutions.

The specifics of the contract-based research were outlined by project coordinator and Associate Professor Evgeniy Zenkov. He has authored around 200 published scientific papers, including an article on the strength of deformable structures in the journal Engineering Solid Mechanics (Scopus, Q1). Previously, the scientist also developed a new method for testing materials under complex loading conditions.

According to Evgeniy Zenkov, cooperation with Irkutsk Oil Company began in 2023. Since then, the research team has completed three R&D projects focused on mathematical modeling of the behavior of pipeline system components used for transportation and gas processing at the Markov oil and gas condensate field. The projects involved specialists from two INRTU departments: the Department of Mechanics and Strength of Materials, and the Department of Mechanical Engineering Design and Standardization. The team possesses the necessary experience and expertise to carry out such work.

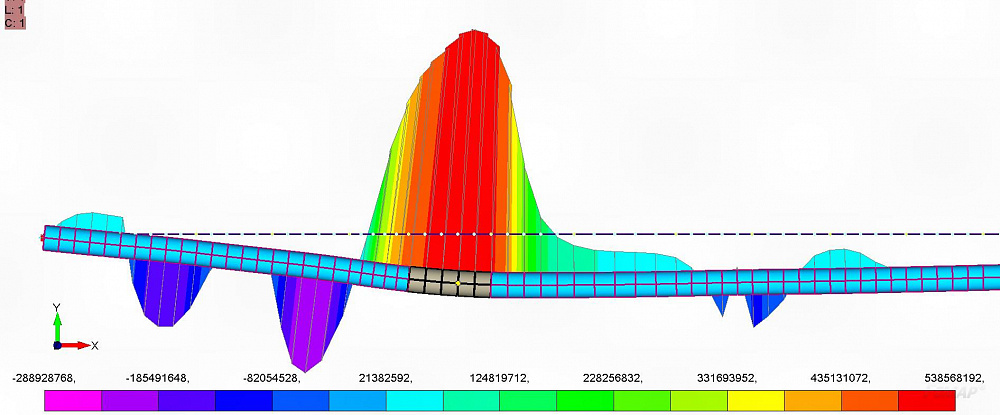

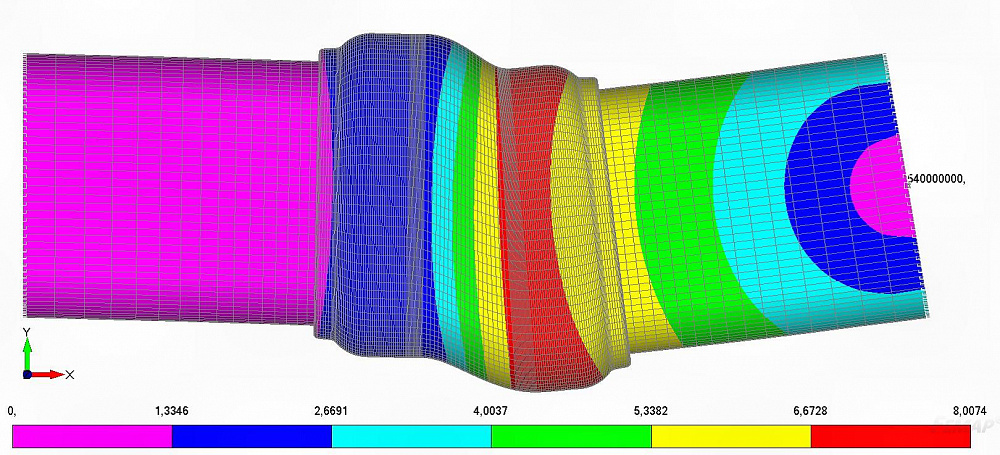

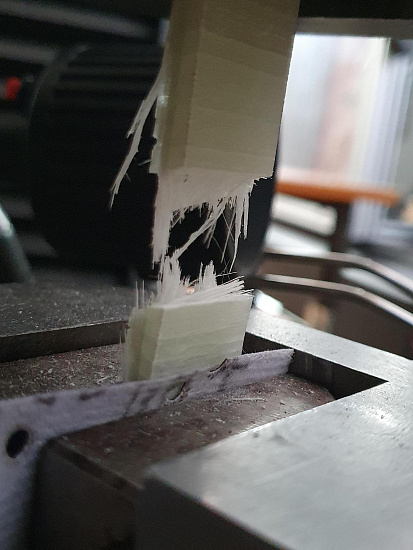

The first project carried out in the interests of IOC focused on studying the strength of fiberglass insulating inserts used in pipelines. The researchers simulated their behavior under load while taking into account key operational factors, including material properties, temperature fluctuations, internal pipe pressure, and displacements of reference points along a specific pipeline section. For this, INRTU team used specialized software. The ultimate goal of the study was to identify the causes of ins ert damage. The mathematical models incorporated actual mechanical properties of the materials, determined through laboratory testing at the INRTU Research Laboratory of Testing of Building Materials and Structures.

Another project addressed safety-related issues. The client set the task of selecting appropriate methods and tools for monitoring the safety of pipelines at an oil well cluster site in Eastern Siberia.

“We analyzed various modern technologies and described their physical and technical implementation mechanisms. We then selected specific technical solutions. In essence, the reliability of operational pipeline systems increases with a comprehensive monitoring approach. This implies using two methods. The first is based on measuring the spatial position of structural pipeline elements using inclinometers, geodetic leveling of reference points, and similar techniques.

The second method involves measuring deformations in highly loaded structural elements with strain gauge sensors. The key conclusion drawn from this work is that rapidly developing methods should not be overlooked, particularly those based on magnetometry, including the assessment of coercive force in pipeline elements, the use of the Forster effect, and related techniques,”

said Evgeniy Zenkov.

The INRTU specialists plan to continue their cooperation with Irkutsk Oil Company. The next project will focus on the design of oilfield pipelines and will aim to improve methods for strength calculations of pipeline structural elements. The details of the project are currently being coordinated with the client.