INRTU Creates Unique Equipment to Form Large-size Aircraft Parts

INRTU scientists have created unique facility for forming and straightening aircraft frame and skin parts.

The work is carried out under the Priority-2030 Federal Program. The introduction of the equipment solves the issues of import substitution and allows to reduce the labor intensity in technological processes by 2-3 times.

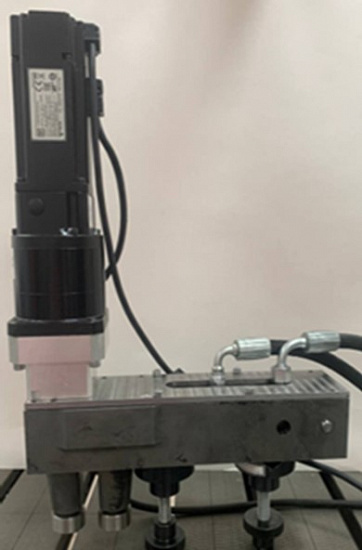

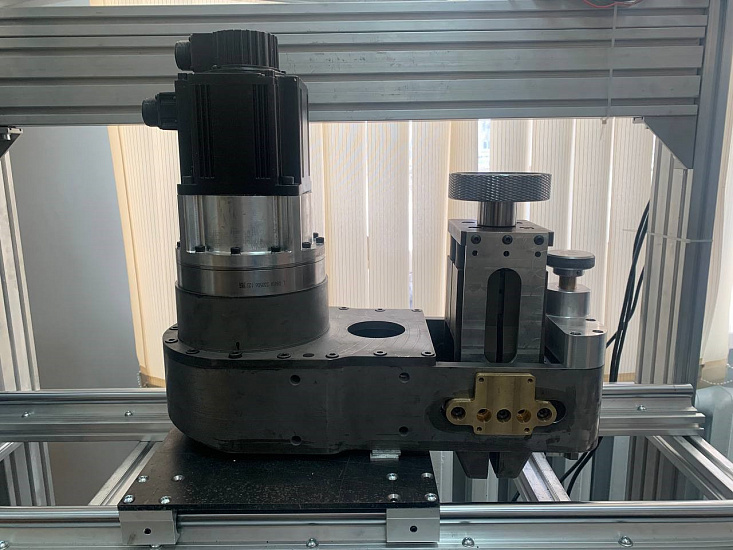

These devices are mainly used to form and correct rib support aircraft parts such as panels, profiles, ribs, frames, etc., Their application as a part of the equipment, in particular, allows to set up to technological capabilities of well-known imported ECKOLD machines.

Reinforced frame parts are prone to warping after milling, and straightening them by the traditional pressing method is rather problematic. Therefore, domestic aircraft manufacturers are most interested in the controlled correcting technology to be created. INRTU patented devices for rolling and placing the reinforced parts ribs have no analogues.

The devices for parts forming and straightening were designed, manufactured and tested by the team of the Digital Design of Mechanical Engineering Process Laboratory headed by a young scientist Alexander Pashkov. Based on these devices INRTU is currently creating technological equipment.

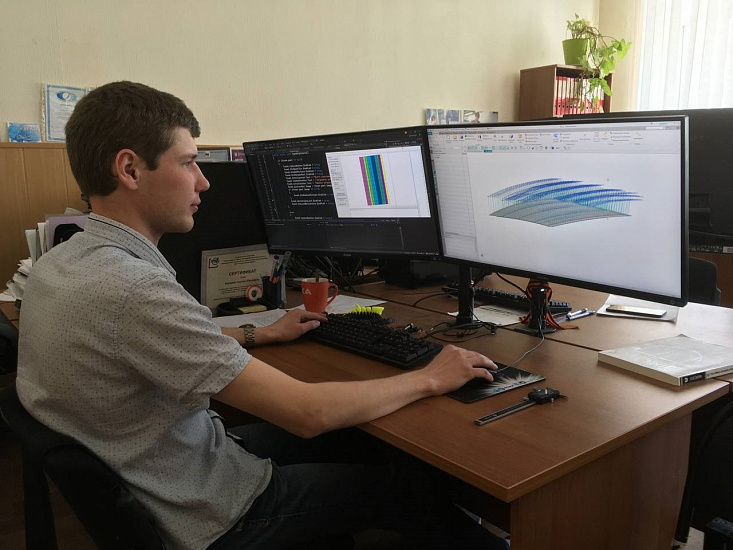

Postgraduate students made a great contribution to the development. For example, Andrey Duk designed a placing tool, Oleg Samoilenko defended his PhD thesis on roller straightening of reinforced frame parts, Sergey Faleev developed technological software for determining modes of forming/adjusting parts based on their CAD models.

"Significantly, the project to create technologies and equipment for forming and straightening airframe and skin parts is being implemented under the import substitution. We are ready to develop it and offer domestic aircraft builders solutions adapted to the manufactured products design features," emphasized Associate Professor Alexander Pashkov.

INRTU engineers managed to design the equipment thanks to the scientific school founded by Andrei Pashkov, Director of INRTU School of Aircraft Construction, Mechanical Engineering and Transport. The scientific school's key development is a combined technology and facility for the aircraft panels and skins forming. The technology was tested in pilot production of TU-204 and TU-334 panels, and then in 2000-2012 in the production of wing panels for the BE-200. In 2021 the mobile filtration unit UFP-1 was introduced at PJSC IL Aviastar aircraft factory, Ulyanovsk.

Today Andrey Pashkov is engaged in organizational activities, negotiating with customers. He points out that all the “land” work is managed by his students. His son Alexander Pashkov became interested in science in his third year of study. The young scientist's research interests include the creation of complex technologies and equipment for manufacturing large-size and low-rigidity parts.

Science-intensive engineering activity is developed by another Professor Pashkov's student Yuri Ivanov. Deputy Director for Science of the School of Aircraft Construction, Mechanical Engineering and Transport has an experience of working at Irkutsk Aviation Plant. Yuri Ivanov is Head of the Digital Technologies for Manufacturing the Polymer Composite Materials Products Laboratory, he is also establishing his scientific school.

Photos provided by Alexander Pashkov