Priority 2030 Program: Intelligent Vibration Analyzer by INRTU will be tested at Novo-Irkutsk Combined Heat and Power Plant

The meeting of the Scientific and Technical Council of the University Development Program was held on 8 December, during which the employees of the university presented the final reports on the implementation of the Priority 2030 program projects.

As previously reported, INRTU allocated 2.5 million rubles to support five scientific initiative groups. The grants were awarded to the employees performing the promising research within the two university strategic projects - i.GeoDesign and i.DIT.

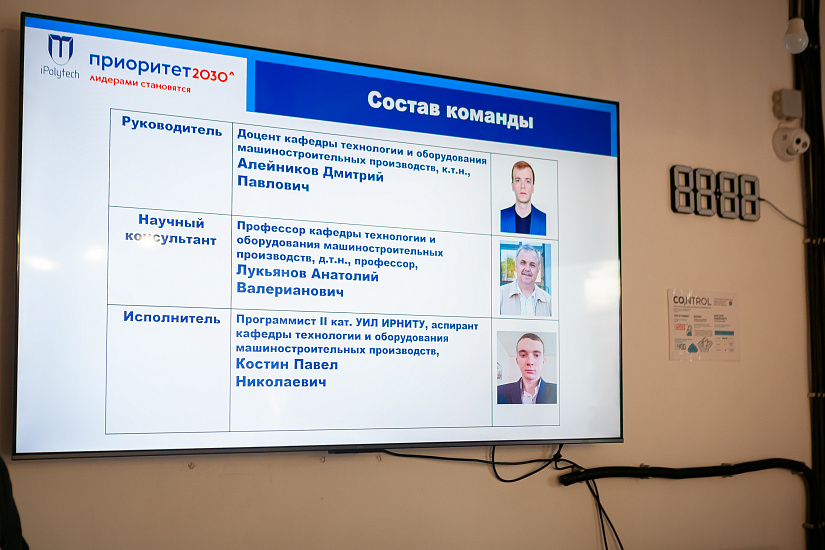

Dmitry Aleynikov, Associate Professor at the Department of Technology and Equipment for Machine-Building Production, demonstrated a prototype of an intelligent vibration analyzer for industrial machinery. The research team also includes Professor Anatoly Lukyanov, who acts as a scientific advisor, and Pavel Kostin, postgraduate student.

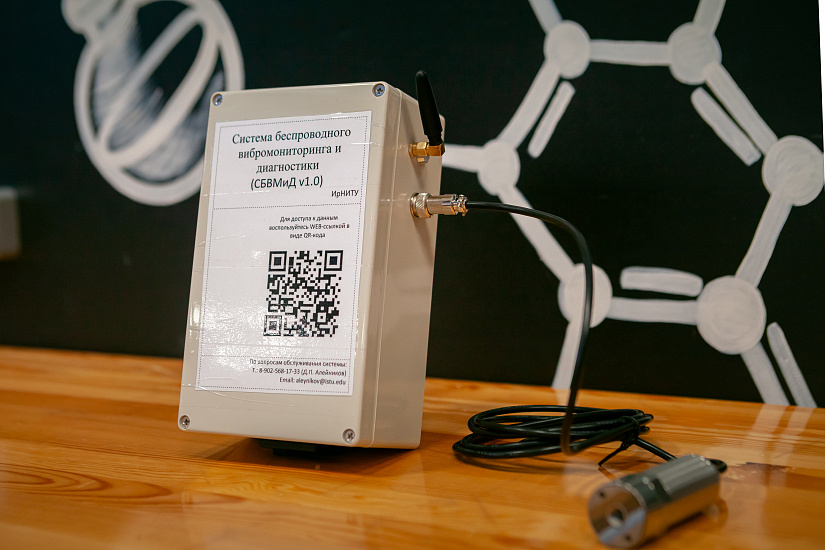

The intelligent vibration analyzer makes it possible to identify equipment defects at an early stage and alert repair services even before a malfunction occurs. This reduces the risk of emergency downtime. The device developed by the INRTU engineers consists of a sensing element, vibration detection and analysis unit. The system is wireless, the interaction between the interface and the device is carried out by scanning a QR code.

"Our work has been successfully completed, the planned indicators achieved. We performed analysis of rotor equipment to determine diagnostic characteristics of the equipment and developed the vibration analyzer prototype. We presented the device to Novo-Irkutsk Combined Heat and Power Plant (CHP). The management of the enterprise was interested in our device. The cooperation protocol was signed with the potential customer. The vibration analyzer has been modified to meet the needs of the CHP, and in the near future it will be installed on one of the centrifugal pumps. After the test operating cycle we plan to conclude a contract with Novo-Irkutsk CHP for the supply of the devices. The enterprise's need for vibration analyzers is more than 100 units," said Dmitry Aleynikov.The research team prepared two scientific articles (citation databases: Higher Attestation Commission, Scopus) and submitted the materials to Rospatent to register the computer program.

The report of the vibration analyzer developers was recognized as the best at the international conference ‘Transport Infrastructure of the Siberian Region’, which took place on 19 November.

The funds allocated for this project in the amount of 500 thousand rubles were spent on salaries and purchase of components. In the interests of the project Dmitry Aleynikov underwent an internship in the BALTECH Research & Production Company, the leader of the Russian market of modern technologies of technical diagnostics and non-destructive testing of industrial equipment & machinery.

The participants of the Scientific and Technical Council of the INRTU Development Program approved the report of Dmitry Aleynikov's team.

It should be noted that the researchers has been working on the subject of vibrodiagnostics for several years. Under the guidance of Anatoly Lukyanov he has developed a system of vibration isolation and shock protection and diagnostics of machining centers, providing high performance parts processing modes. The prototypes have already been introduced by the Irkutsk Aviation Plant.

Photos by Arseny Chekmaryov