INRTU Develops High-Strength 3D Printed Tooling for Aircraft Parts

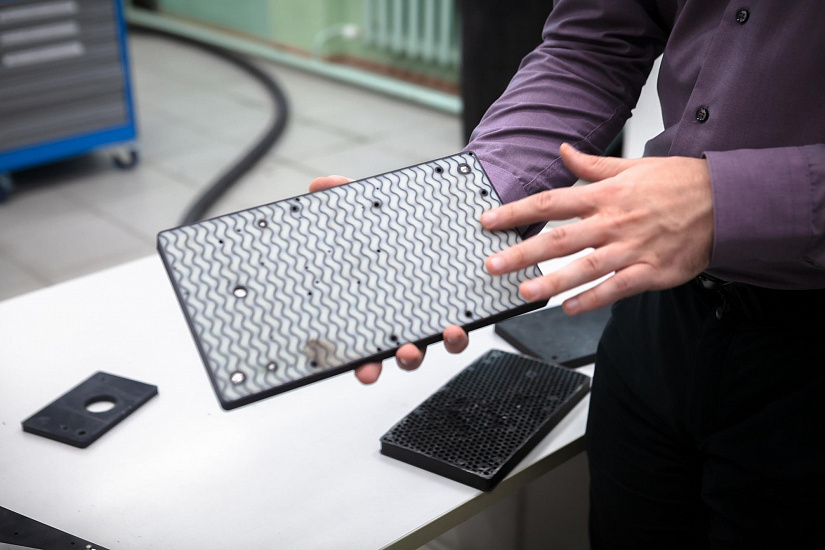

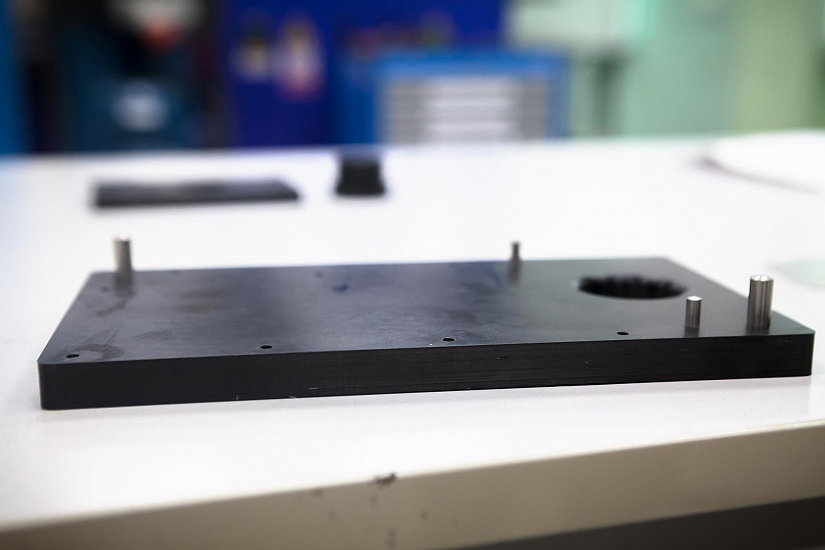

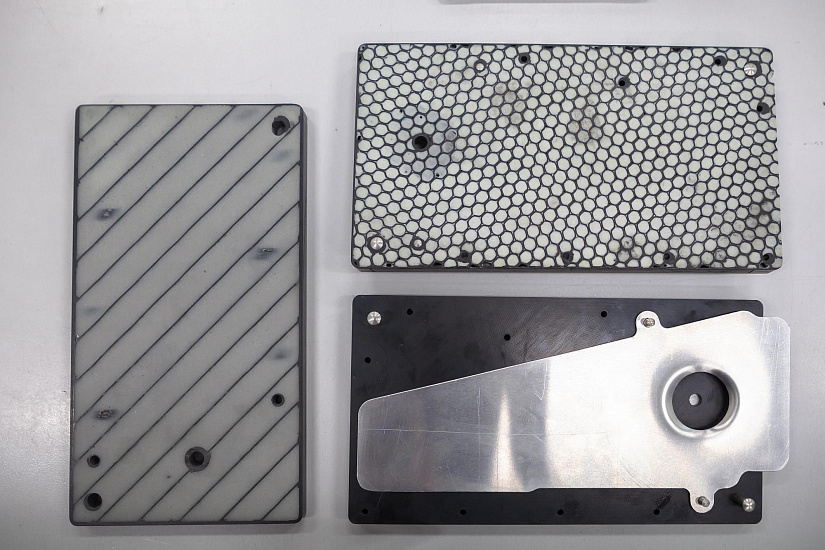

INRTU employees apply 3D printing technology to create polymer tooling for stamping sheet aircraft parts. The printed plastic mold allows to reduce the time of pre-production compared to the traditional analogues of aluminum or steel tooling. The experimental model developed by INRTU engineers withstood the forming of a 1.5 mm thick aluminum blank. Compared to the 3D printing of a solid model, the proposed method allows for four times faster tooling production (12 hours instead of 48). The technical solution is the result of the University's work under the Priority 2030 program.

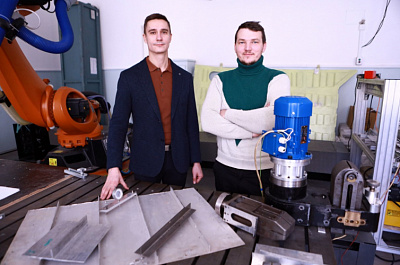

The work is carried out by the team of the Digital Technologies for Polymer Composite Products Manufacturing research laboratory headed by Yuri Ivanov. The team includes research engineer Anton Sturov, research laboratory assistant Lev Shemetov, training master Evgeny Semenov.

As Lev Shemetov explained, 3D printing technology using plastics is considered promising in the aircraft industry due to the labor-intensive mechanical processing involved in making tooling from steel or aluminum. Specialists at the Irkutsk Aviation Plant, a Yakovlev Corporation branch, have shown great interest in these new manufacturing methods. It is crucial for the plant's engineers to address issues related to the resources required for tooling and its durability.

"The laboratory team has implemented a new technical solution. For the casting process, we use reactive plastics - materials that can harden like concrete. By experimenting with casting technology and special mold fillers, we tested glass powder, graphite powder, and aluminum dust. Our main goal was to find the optimal composition that would minimize mold deformation under high loads.

The results showed that the printed plastic mold can withstand the working loads of the press exceptionally well. Our proposed technology allows for faster production of tooling at a lower cost," said Lev Shemetov, highlighting the advantages of the development."

The INRTU team plans to present the project to the Irkutsk Aviation Plant to gather feedback from industry professionals and explore the feasibility of applying the technology to the serial production of sheet components.

Photos by Arseny Chekmarev