Study of Samples and Wastewater Treatment in Mining Digitized by INRTU

INRTU has patented a software for the study of samples and wastewater treatment in mining and metallurgical enterprises. The information system, created under the Priority 2030 program, will speed up ore concentration studies five times, reduce the influence of the human factor on test results, and make experiments cheaper for customers - mining and processing enterprises.

According to Alexander Burdonov, Head of the Flotation and Reagent Chemistry laboratory, the university cooperates with the Irkutsk Heavy Machinery Plant (IZTM), Skoltech, and a number of other companies to improve the process of pulp thickening and wastewater treatment. The project was developed to help factories achieve the most efficient ore concentration and closed loop water supply.

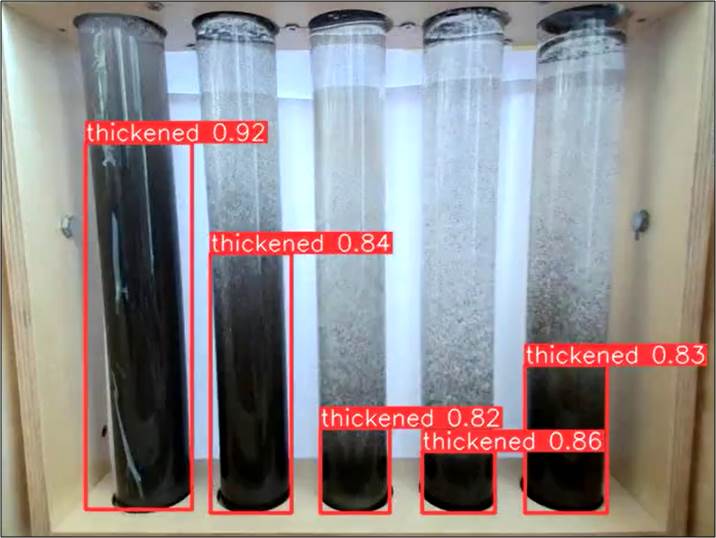

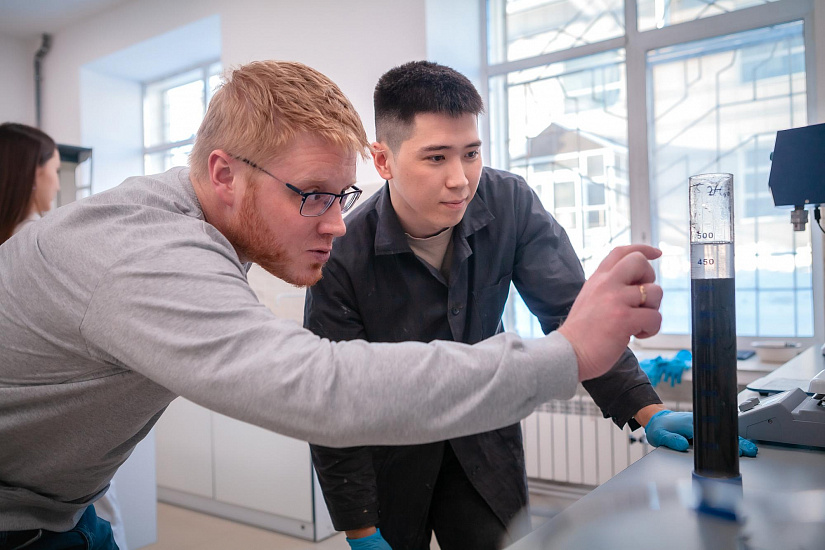

"In the cylinders we mix the pulp with water and reagents and monitor the dynamics and quality of particle deposition. The sedimentation process is labor-intensive and subject to human error. Large errors can occur in calculations due to the inability to accurately find the interface between the liquid media. For this reason, we have created a facility for simultaneous and qualitative performance of five experiments. Mixing of pulps, recording of observation results and plotting of graphs do not require the active participation of researchers," said Alexander Burdonov.The project also involves a scientist from Skoltech, leading researcher at the Institute of Information Technologies and Data Analysis Dmitry Shadrin, INRTU 2024 graduate Zandan Shonkhodoev, INRTU target Master's student Daniil Skvortsov and Elizaveta Mishnenkova from Voronezh State University.

According to Daniil Skvortsov, the installation is supplemented by a hardware complex including a camera and software for image processing and recording indicators with two computer vision methods. The developed model converts an analog signal carrying information about the boundary level between the two media into a discrete set of numerical values. These are represented with high accuracy for further mathematical processing.

"The flasks contain pulp with added flocculant. After having fixed the flasks in a rotating frame, the researcher starts the shooting mode in the program. The system controls the frame rotation speed and the number of spins. Then the frame stops in the initial position and the process of particle deposition is automatically recorded (10 frames per second). All images are stored in a separate folder. The researcher can use the plotting mode to determine the interface level in each flask. The data is then interpolated and the final graph is generated. The efficiency of scientists' work is increased by digitizing labor-intensive processes," Daniil Skvortsov said about the functionality of the software.

The software program for sample analysis and wastewater treatment may be in demand by mining and metallurgical enterprises, research laboratories and universities dealing with mineral processing. The product can be commercialized in partnership with Institute TOMS (Technologies of Mineral Separation), Promkhimservis, Polyus Krasnoyarsk, IZTM-Engineering and others. The software will be used in project activities and educational process within ‘Dehydration’ and ‘Dust Collection and Wastewater Treatment’ courses.

Photos by Arseny Chekmariov and Daniil Skvortsov