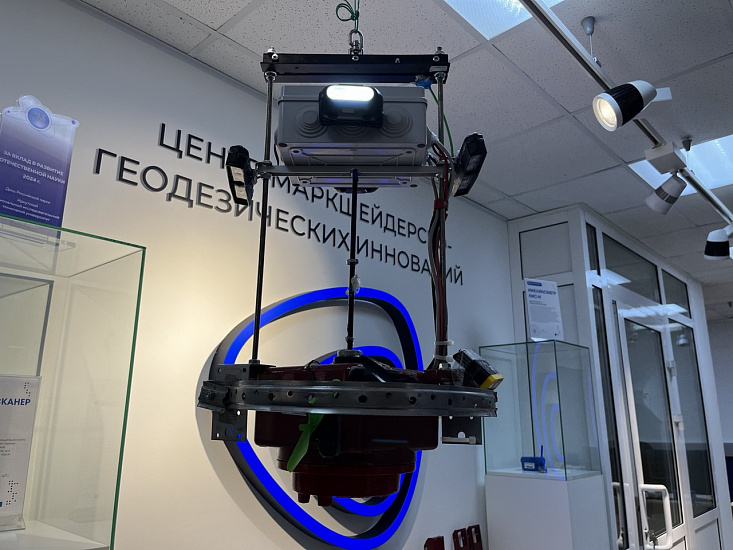

ScanDinAvia. INRTU's Innovative Solution for Vertical Mine Shaft Inspection

Researchers at INRTU's Center for Mine Surveying and Geodetic Innovations have developed ScanDinAvia, a cutting-edge deep mine inspection system. Developed as part of Russia's Priority 2030 program, this advanced device will help mine surveyors tackle one of the industry's toughest challenges: inspecting vertical shafts without existing elevator infrastructure.

The system was created by a team fr om the Design Engineering Department of the Center for Mine Surveying and Geodetic Innovations - Semen Gridnev, Alexander Tokin, and Yaroslav Malmygin.

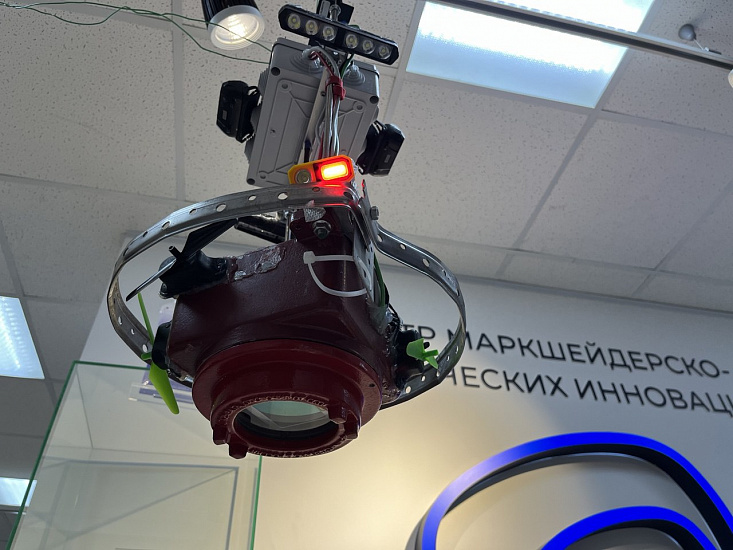

As Сhief Engineer Semen Gridnev explained, the deep mine shaft inspection device integrates several advanced technologies. The winch-based system, equipped with a video camera and laser scanner, maintains precise stabilization even under intense ventilation and at extreme depths. The resulting point clouds are processed using two proprietary methods, both implemented in custom software developed by the INRTU team specifically for this project.

The system works by using a stabilization motor to counteract the rotation of the unit in the shaft through reverse blade motion. Swing stabilization is achieved by using accelerometer and gyroscope data to control four motors located on the sides of the unit. These motors drive the propellers against the detected accelerations, thereby damping the swing amplitude.

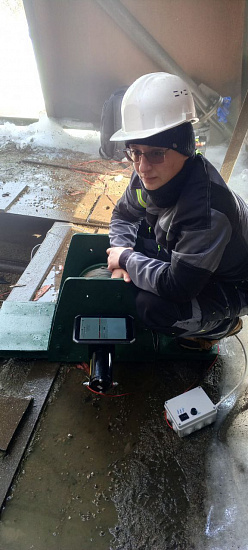

"This device was designed from scratch and assembled in just six weeks. Its field testing was conducted at Priargunsky Mining and Chemical Association named after E.P. Slavsky, а Rosatom company, wh ere we refined the design during actual operations."

Gyroscope and magnetometer data confirmed the high efficiency of our system in challenging environments (extreme depths, intense ventilation, reinforced structures), maintaining stable device positioning and high-quality video documentation of shaft conditions. I must emphasize that all mine workings require periodic inspections under the safety regulations.

Azimuth data, scanner readings and depth measurements were transmitted in real time to the control panel via a high-speed radio link. Despite the numerous obstacles and metal structures in the surveyed mine shafts, there were virtually no signal interruptions. Both the winch and the depth measurement unit worked without a hitch," Semen Gridnev said of the test results.

The chief engineer noted that a year earlier, Norilsk Nickel had approached INRTU's mining surveyors with a similar issue involving ventilation shaft inspections:

"After the successful completion of the project at Priargunsky, ScanDinAvia is ready to work with Norilsk Nickel and other clients."The INRTU engineering team plans to conduct additional testing with upgraded stabilization motors and develop more sophisticated control algorithms for operation under extreme ventilation conditions.

Furthermore, the team is considering integrating additional sensors, such as thermal imaging equipment, to enable more detailed analysis of shaft conditions.

Photos by INRTU Press Service and Semen Gridnev