Priority 2030 Program: Intelligent Vibration Analyzer for Industrial Machinery Upgraded by INRTU

INRTU experts have modernized an intelligent vibration analyzer for industrial machinery diagnostics. Customers of the upgraded device will be the Novo-Irkutsk Combined Heat and Power Plant (CHPP) and Irkutsk Oil Company (INK).

The vibration analyzer was developed by the Department of Technology and Equipment for Machine-Building Production under the Priority 2030 Program. For implementation of this project in 2023, INRTU allocated a grant of 500 thousand rubles. This year the developers received the same support.

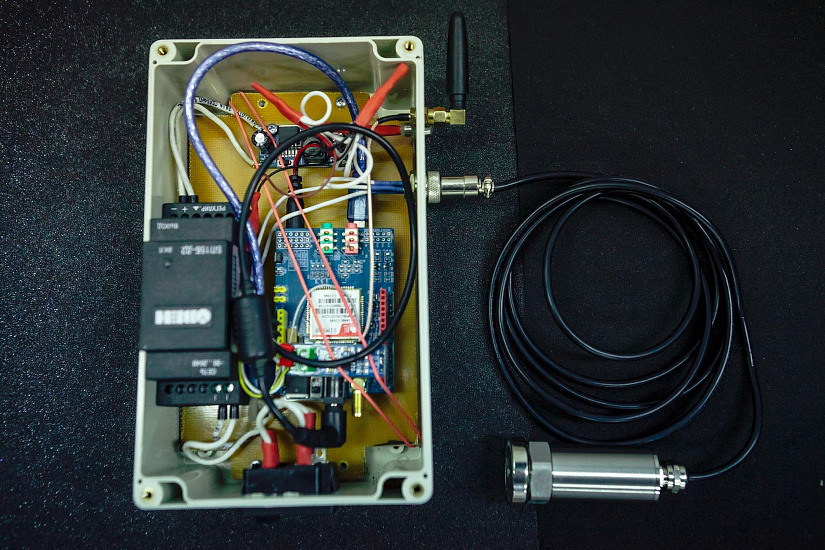

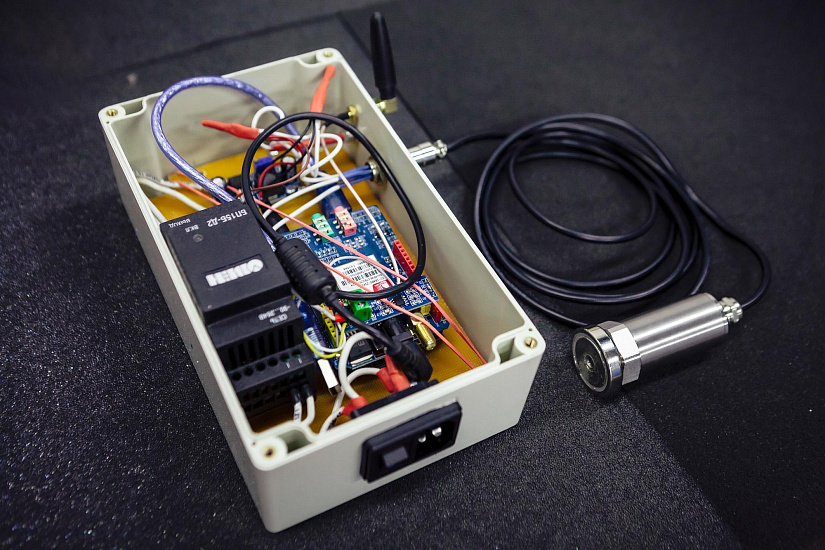

The intelligent vibration analyzer can detect equipment defects early. This helps to reduce the risk of emergency downtime and avoid costly repairs. The first prototype of the device was tested at the Novo-Irkutsk CHPP. Then INRTU chose to improve the device.

According to Dmitry Aleynikov, Associate Professor of the Department and project manager, the predecessor of the new model worked from the power grid, which limited its use in hard-to-reach places. The upgraded vibration analyzer is characterized by a built-in rechargeable battery, as well as the number of vibration measurement channels, software with a module based on machine learning.

"Another important advantage is the increase in the number of sensors. The improved vibration analyzer performs measurements in the vertical, horizontal, axial and tangential directions," says Dmitry Aleynikov.

Along with Dmitry Aleynikov, Professor Anatoly Lukyanov, Associate Professor Alexey Isachenko, postgraduate student Pavel Kostin and second-year student Eva Pidugrskaya from INRTU School of Aircraft Construction, Mechanical Engineering and Transport are working on the project.

This year Vladimir Naletov, a talented programmer from the Design and Technology Bureau, joined the team. He completed the software of the device and created a user-friendly interface with high-quality data visualization. On the web page you can watch the parameters of vibrations, temperature changes in real time.

The vibration analyzer will be installed on one of the centrifugal pumps of Novo-Irkutsk CHPP. In addition, Irkutsk Oil Company is interested in the device. The parties are currently negotiating cooperation.

"If the test is successful, we intend to produce a batch of vibration analyzers and provide them to companies free of charge. This will allow us to measure our customers' equipment and later provide vibration adjustment services. For this purpose, the university has purchased special equipment from BALTECH," said Dmitry Aleinikov.The researcher has been working on vibrodiagnostics for several years. Under the guidance of Anatoly Lukyanov, he has developed a system of vibration isolation and shock protection and diagnostics of machining centers, providing high-performance parts processing modes. Prototypes have already been introduced by the Irkutsk Aviation Plant (Yakovlev Branch).

Photo by Arseny Chekmaryov