Plant Heating Mats Based on Carbon Paste Produced by Igor Shelekhov, Associate Professor at INRTU

INRTU employee Igor Shelekhov invented mats for heating seedlings and indoor flowering plants. Products based on carbon paste are cheaper than market analogues, surpass them in quality and safety, and most importantly, accelerate the growth of demanding plants. The launch of mass production is yet being planned, while the summer residents and flower growers can already buy pilot batches.

Igor Shelekhov, Associate Professor of the Department of Urban Planning and Municipal Engineering, has founded a small university spin-off ‘Industrial Technological Innovations’. The company has developed a technology for mass production of carbon paste with the support of the Innovation Promotion Fund. A key area of its application is the creation of conductor and heating elements with a wide range of electrical resistance and increased specific power, stability, durability and reliability.

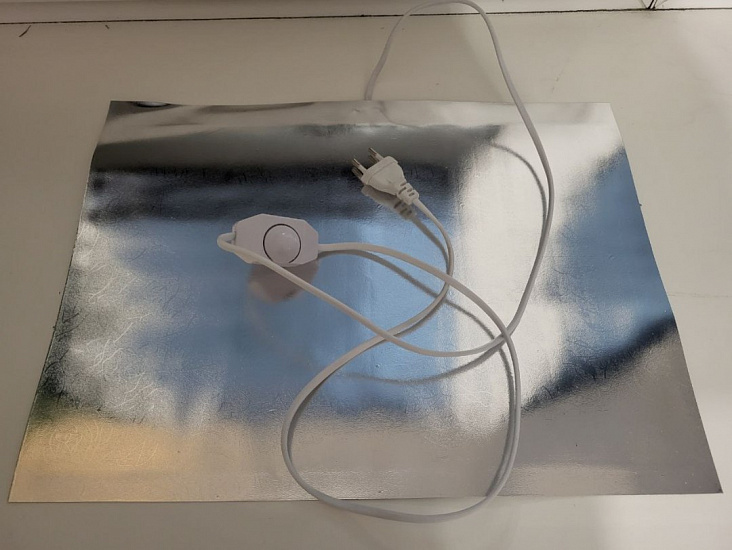

Last winter Igor Shelekhov produced a pilot batch of mats that can be placed under pots with seedlings and indoor plants. The basis of the products consists of heating elements with a uniform heating layer made of carbon paste and protected by polymer. The next layer is heavy duty aluminum foil, which is usually used for finishing kitchen worktops. This foil is aesthetically pleasing, durable and increases heat capacity.

The mats have low power consumption, which affects their cost and efficiency in use. The total power consumption of the elements is 40 W. For a small pot 5 W is enough, for a larger cachepot - 15 W. The author claims that these devices accelerate the growth of even the most demanding plants. His family was convinced of this by personal experience.

"The first experiment I did was with a wild tangerine sprout that was grown from a seed. Neither sunlight nor phytolamps helped the plant. A couple of weeks later, thanks to the mat, it sprouted green shoots. My wife suggested doing the same manipulation with the ‘frozen’ cactus. The effect was similar. It is interesting to note that in the pot with the cactus there was a mango seed planted two years ago. Under the influence of heat, it also sprouted. Then we put mats under all the plants in the house and distributed the heaters to friends. The devices also performed well when drying fruits and herbs. For example, you can dill and parsley can be dried in half an hour," said the author.

The products are presented in a wide range of sizes. The largest scale is 50x50 cm. For plants on the windowsill the optimal sizes are 30x80 cm and 30x40 cm. By the way, the smallest (15x15 cm) mats are the ones that helped Igor Shelekhov's friends to ‘revive’ an indoor dahlia last winter.

The inventor emphasizes that the history of mat creation is directly connected with numerous experiments. It started in the 90s. Then the researcher applied heaters of different configuration in a subsidiary farm. Then in February they began to grow greenhouse cucumbers, tomatoes and herbs in full growth. The demand for products was frantic, but the project could not survive the Perestroika. Almost 30 years later, Igor Shelekhov again drew attention to the use of carbon paste in the agricultural sector.

"Igor Altukhov, Associate Professor at Irkutsk State Agrarian University, came up to me with following problem. For drying vegetables, he used Russian mats bought in a shop. They heat unevenly, in ‘strips’, so he had to turn on the device at higher power. This leads to additional energy costs, and there is a risk of overheating and fire. So Igor Altukhov asked me to think of something more efficient and safer. Market analysis showed that the best-selling product in the heater segment is seedling mats. However, there were few Russian developments. The quality of foreign devices is also questionable. This is how the idea of creating mats with an evenly distributed heating layer came about," noted the inventor.

The average price of a mat on marketplaces is approx. 1,000 rubles for a 30x40 cm product. The researcher offers pilot batches for 700 rubles. The offer is doubly profitable, as the mat comes with a control device and a power cord. Adjusting the voltage and the temperature in the range from room temperature up to 60°C makes the kit universal.

"Our products comply with GOST standards. The heating element and paste production technology have been patented. They have been tested outdoors in an environmental chamber and under temperature fluctuations. At this stage we are making prototypes, which according to the laws of the Russian Federation are allowed to sell in small batches. By the way, it takes a day to make one mat set. The summer season is about to start, so the residents of Irkutsk can already contact us".

The next step is product certification, production of serial batches and full-fledged entry into the market. Hope this will happen by the end of 2024," said Igor Shelekhov.

Business development needs help from people with technical thinking who are willing to participate in in the launch of mass production and sales. Preference is given to engineers, automation engineers, including students. Representatives of economic and creative specialties who have ideas for marketing and design are also welcome to cooperate.

Those wishing to join the project or purchase trial batches please contact Igor Shelekhov by e-mail promteplo@yandex.ru or phone +7 (902) 566-03-23.

Also, the scientist uses carbon paste to create other non-standard products. Last year he invented heated shoe insoles. The products retain heat for up to 12 hours, which is superior to market analogues. A small batch of the insoles was sent to the soldiers of the Special Military Operation as humanitarian aid.