Machine Builders Gain Edge: INRTU’s Innovative Variable Tooth Pitch End Mill to Damp Vibrations and Increase Output

Researchers from the INRTU Design and Technology Bureau (DTB), in collaboration with the Irkutsk Heavy Machinery Plant (IZTM), have engineered an innovative end milling cutter with variable tooth pitch. The unique design of this cutting tool eliminates harmful vibrations, extends the tool’s lifespan, and enhances metalworking precision. The project is part of the Priority 2030 program.

The project addresses a critical issue in machining - face milling operations generate significantly higher vibration levels than other metalworking processes. Minimizing these vibrations ensures reliable tool performance and enhances the stability of the entire machining system, which are both key factors for industrial efficiency.

Andrey Irincheev, a design engineer at INRTU's DTB, says that tool design plays a crucial role in vibration damping. As the most vulnerable component of the machining system, tools with poor vibration resistance lead to accelerated wear, dimensional inaccuracies, and decreased process efficiency.

"The primary purpose of an end mill is to remove large amounts of metal from the workpiece. At IZTM, however, milling operations are performed with significant spindle overhang, dramatically increasing vibration levels. This results in poor surface quality and rapid tool wear, which significantly impacts production efficiency.

Unwanted vibration harmonics can be suppressed through the mill's variable tooth pitch design. While many existing cutters employ this principle, they all have one critical limitation: their variable pitch is either fixed or has a very narrow adjustment range. Our breakthrough lies in our ability to create customizable angular spacing between teeth, which enables superior vibration damping. We have provided a broad range of adjustable tooth pitch," Andrey Irincheev commented on the development's special features.

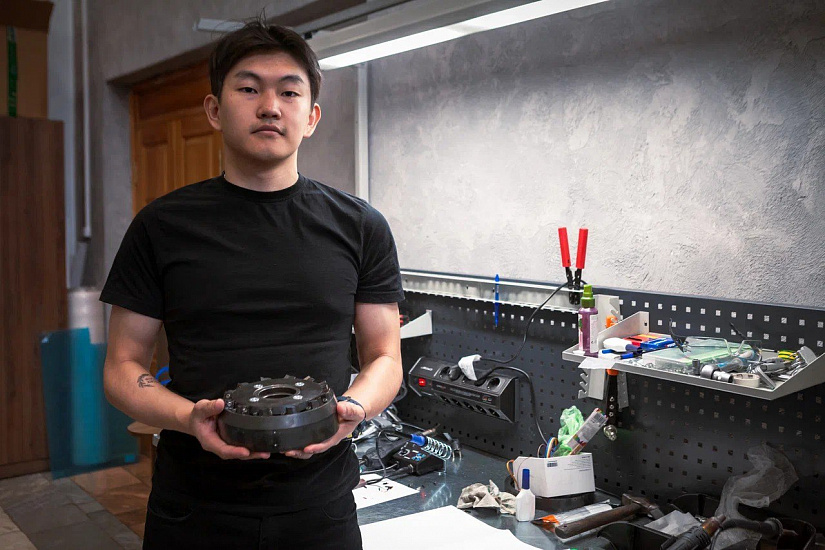

The prototype comprises over 20 components produced by INRTU's High-Performance Machining Technology Research Laboratory team.

"The team is preparing a patent application while gearing up for performance trials. We will test the cutter on metal workpieces supplied by IZTM under varying conditions. Starting with light cuts, we'll progressively increase the metal removal rate picking up the tooth pitch configuration to reduce the amount of vibrations to a minimum. The project is supervised by Prof. Valery Svinin from the Department of Technology and Equipment of Machine-Building Production," the design engineer added.The INRTU team also plans to implement a multi-level cutting scheme with teeth positioned at different heights. This will enable deeper metal removal and increase machining productivity.

Photos by Arseny Chekmarev