INRTU Surveyors Performed Mine Shaft Profiling at the Skalisty Mine by Nornickel

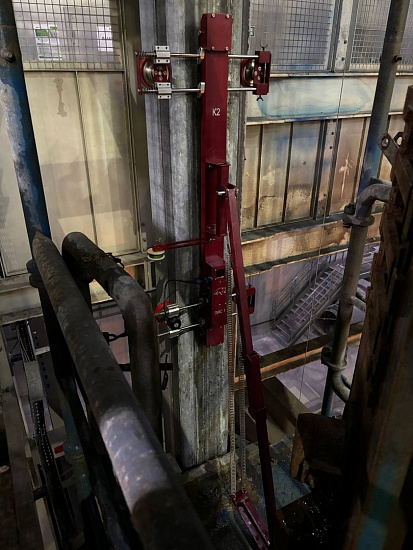

Semyon Gridnev, chief designer of the Center for Surveying and Geodesic Innovations, and Danil Kirikov, 4th year student, performed profiling of the super-deep mine shaft SKS-1 (2050 m) at the Skalisty mine. The work was commissioned by the Polar Department of PJSC “MMC “Norilsk Nickel” – (Nornickel), Krasnoyarsk Region. INRTU used the LIS-1 (Laser Measuring System) station designed by Semyon Gridnev to control the parameters of the shaft. The equipment was developed under the Priority 2030 Program. The station is included in the catalogue of import substitution exchange created by the Ministry of Industry and Trade and the Ministry of Digitalization of the Russian Federation.

According to Semyon Gridnev, the university conducted a survey audit during the construction and hanging of the conductors in the shaft, made recommendations for eliminating defects, and conducted a control profiling of SKS-1. According to safety regulations, vertical mines should be inspected every three years.

"The shaft has a cage with five levels, each of which is easily accessible by a loading and delivery vehicle. The structure is impressive in its size, being the deepest in Eurasia. We performed measurements in the cage and counterweight compartment, including conductor profiling and determination of safety clearances with obtaining a point cloud," said Semyon Gridnev.

During the work there was a strong drip (water accumulation), the temperature outside was minus 33 degrees Celsius and in the shaft - minus 10 degrees Celsius. Despite the extreme natural conditions, the LIS-1 underground laser scanner remained operational.

"On one of the carriages, a track sensor failed during profiling of the counterweight compartment. However, this did not affect the survey results. The LIS 1 design is fault-tolerant. In case of strong interference and obstruction of wireless data transmission, the station starts in an autonomous mode. The carriages are not connected and write data independently, each to its own internal memory.The LIS 1 station can work with only one of the carriages. If carriage 2 fails, it can be replaced by a working carriage and measurements can be taken. The non-functioning carriage is put into idle mode to maintain the integrity of the structure," Semyon Gridnev explained.

Danil Kirikov, an SNO Alidada activist, worked at the Skalisty mine for the first time. The INRTU student is now being trained to perform mine profiling for various companies on a regular basis.

"Earlier, together with Semyon Olegovich, I visited the Mariinsky Mine in the Sverdlovsk Region. Now I had the opportunity to work at such a large facility as the Skalisty mine. I gained a lot of experience working with unique equipment. At the same time, business trips broaden my personal and professional horizons," says Danil Kirikov.

The design of the LIS 1 station has been successfully applied in the Berezovsky Mine, Priargunsky production mining and chemical association, Kholbinsky Mine ("Buryatzoloto"), Gremyachinsky GOK ("EuroChem-VolgaKaliy"), the equipment is permanently improved, the station has been modified to LIS 1M.

Photo by the Siberian Meridian group in VK