INRTU Researchers Study the Physical and Mechanical Properties of Polymers

The research team of the Department of Mineral Processing and Environmental Protection named after S.B. Leonov, School of Subsurface Resource Management, has carried out a study of the physical and mechanical properties of polymers. The customer of this research project was ElTech.

The project team was led by Associate Professor Alexander Burdonov and included the future ecologists and enrichment experts. The students showed great interest in solving the new case as they work more with minerals, stated the teacher.

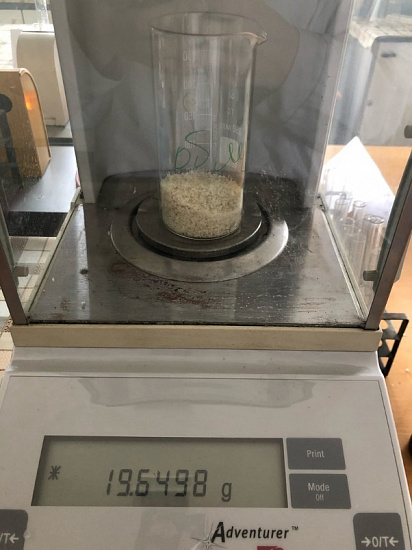

“The Department of Mineral Processing and Environmental Protection has been studying polymers and composites since 2009 and they have a good professional experience. The scientific director is Professor Elena Zelinskaya. Quite a few projects have been implemented on the subject with the involvement of various funding sources. Students, who took part in the ElTech project, also obtained skills in polymer research”.As Alexander Burdonov noted, at the first stage the team was to determine the solubility of polyethylene granules in organic substances. The experiment was carried out at different temperatures. “The size of the factory polymer is 2-2.5 mm. With the help of the thermoplastic machine installed at the department, we prepared the material samples, downsized them with a shredder to 0.5 mm. Then they observed how the material behaved in the solvent, took the weight and volume readings, set dependencies, built graphs. The pre- and post-drying values of polyethylene are 39.06% and 2.58% accordingly, which is higher than the initial material had”, said Alexander Burdonov.

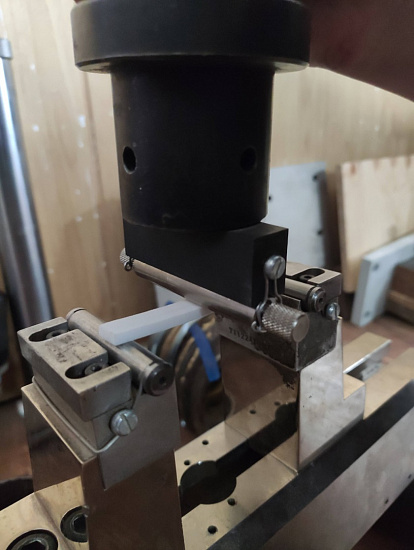

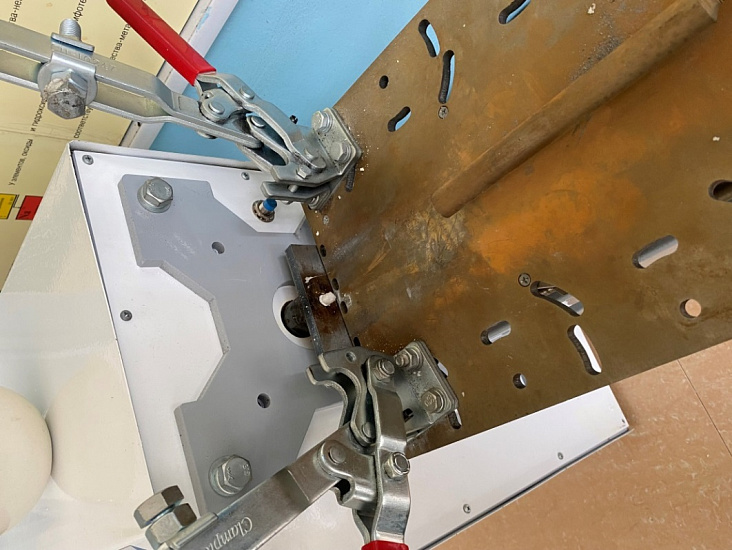

The second stage was to study and increase the physical and mechanical properties of polyamide products. In the laboratory, students and staff performed bend test of the polymer and other analyses using the universal electromechanical testing machine INSTRON 5989. The hardness was determined by the Shore and Brinell methods. Experiments showed that the initial samples were fragile. On the contrary, the material prepared by the research team turned out to be solid and resistant to destruction.

Photos by INRTU press office and Alexander Burdonov