INRTU Patents High-Precision Lining Wear Assessment Software

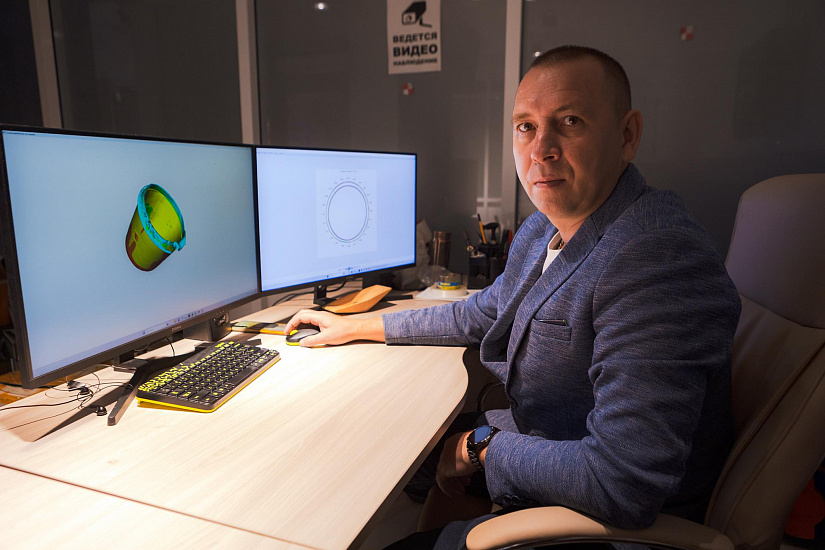

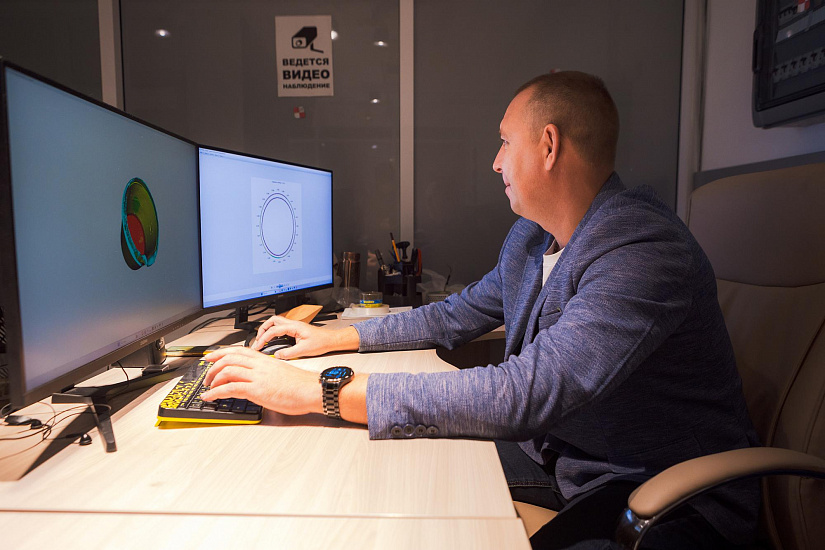

Alexander Tokin, a lead research scientist at INRTU Center for Surveying and Geodesic Innovations, has patented a software program called "LIS-Lining Profiler". The software uses laser scanning data to accurately calculate the thickness of the internal lining of industrial boilers and furnaces. This development will enable mining, metallurgical, and chemical enterprises to service their equipment in a timely manner, thereby extending its lifespan and preventing accidents. The "LIS-Lining Profiler" software was created as part of the Priority 2030 program.

The innovative lining thickness calculation process involves several stages. First, engineers perform laser scanning of the equipment before and after the lining is applied to generate high-precision point clouds. The software then automatically aligns these scans into a single 3D model, removes noise and extraneous elements, and brings the data into a unified coordinate system. In the final stage, it performs a comparative analysis of the two scans and calculates the lining thickness. The results are clearly visualized through color-coded scans (where color indicates lining thickness) and point cloud cross-sections.

Alexander Tokin emphasizes that this method is an innovative application of laser scanning and digital technology to solve engineering problems.

"The advantage of the 'LIS-Lining Profiler' software lies in its ability to eliminate errors inherent in manual measurements and visual inspections. Timely and precise monitoring of the lining condition will allow companies to optimize maintenance schedule, reduce spending on spare parts and services. As a result, equipment operates longer without downtime, withstands design loads, and ensures the stability and reliability of the entire production cycle," highlighted Alexander Tokin.

As previously reported, Semyon Gridnev, chief designer at the Center for Mine Surveying and Geodetic Innovation, has developed a line of "LIS" instruments. This product family includes the "LIS 1" and "LIS 1M" stations for mine shaft profiling, the self-propelled "LIS-Virgil" vehicle capable of inspecting wells over 100 meters deep; and a smart network of inclinometers designed to find structural deformation in buildings and engineering structures.

Photos by Arseny Chekmarev