INRTU Innovates in High-Impact Resistant Composite Materials

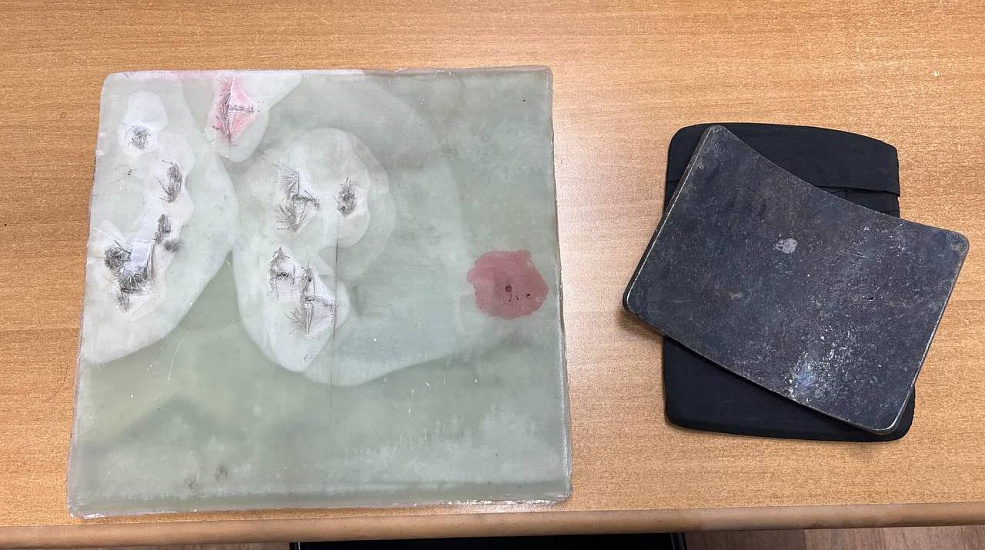

INRTU School of Aircraft Construction, Mechanical Engineering and Transport has developed lightweight composite materials with increased impact resistance. Using additive technologies, INRTU experts were able to reduce the thickness of the steel several times without losing the impact resistance properties.

Work on the project was led by Andrei Balanovskii, Head of the Department of Materials Science, Welding and Additive Technology. The development team included postgraduate students Georgy Mikhailovsky and Ruslan Gusev, and master's student Pavel Zakharov.

According to Andrei Balanovskii, the composite materials were created using an industrial robot manipulator purchased under the Priority 2030 program. In total, about 10 parts made of titanium, aluminum, fiberglass, and steel were developed. Each sample was tested for impact resistance in a special testing facility.

"The effectiveness of armor ballistic protection depends on the material's ability to absorb and disperse threats that impact the surface. Upon impact, the armor can deform, return energy to the threat, or dissipate it. The mechanical properties of the material the armor is made of affect the degree to which this energy is dissipated.

During testing at the range, a sample made of steel performed well. This iron alloy is the main one used in the production of armored vehicles. Its advantages include high ballistic properties and low cost,” says Andrei Balanovskii.

The team was tasked with reducing the thickness and weight of steel plates. To do this, they used additive technologies to create a gradient functional material on the steel plate surface. This approach allowed for a significant reduction in plate thickness, greatly lightening the plate without losing its impact-resistant properties.

"We were pleased with the results and are eager to further enhance the material by increasing its impact resistance. Such properties are crucial for various manufacturing industries that demand high levels of impact resistance," added Andrei Balanovskii.Postgraduate student Georgy Mikhailovsky noted that the composite material was "grown" using the method of wire-arc welding:

"Working on this project has significantly improved my skills in the creation of composite materials. This experience will be beneficial when I prepare my PhD thesis on laser alloying. The primary goal of the research project is to develop a technique to improve the wear resistance of components that come into contact with soil or rock".

Currently, the staff of the Department of Materials Science, Welding, and Additive Technology are conducting R&D tailored to the needs of automotive and aircraft industries.

Photos by INRTU Press Service