INRTU Develops High-Tech Electric Drilling Machine for the Irkutsk Aviation Plant

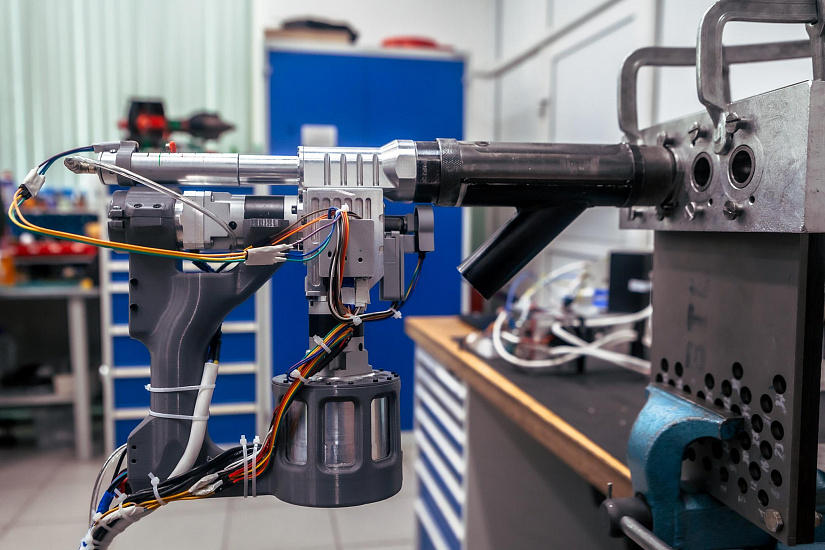

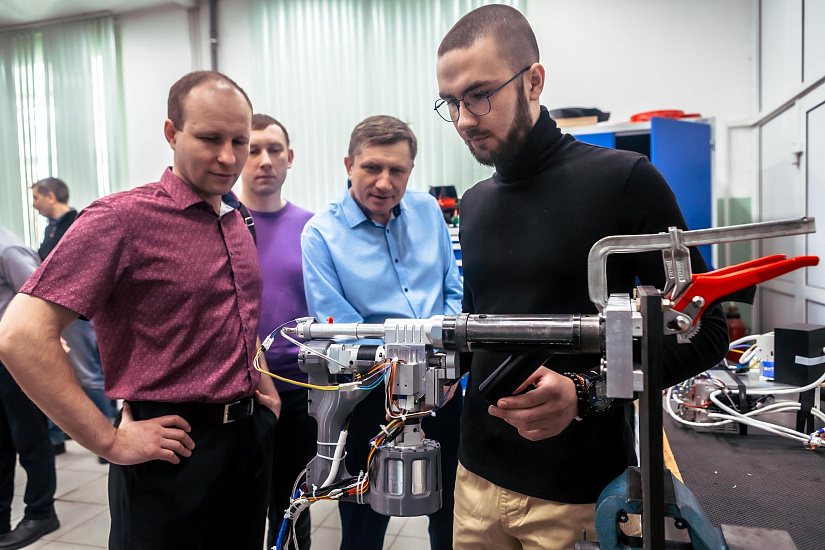

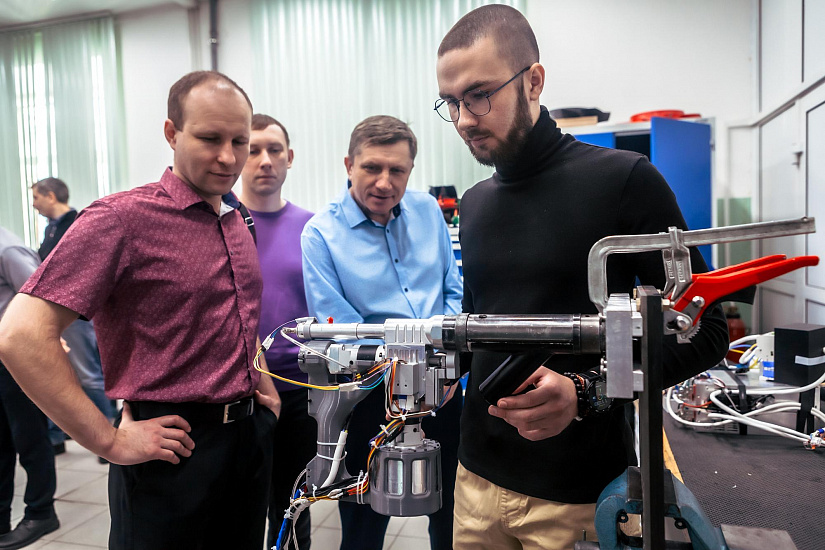

INRTU Design and Technology Bureau (DTB) presented a sample of an electric auto feed drilling machine (AFDM) to the Irkutsk Aviation Plant, a Yakovlev Corporation branch. The tool improves the quality and productivity of drilling of multi-layer aircraft parts (composite-steel-titanium-aluminum), competing with foreign analogues. The main advantage of the INRTU drilling machine is the ability to assign drilling modes for each layer of material.

The engineering and technical solution is the result of cooperation between the DTB and the Research Laboratory of Digital Technologies for the Production of Polymer Composite Materials under the Priority 2030 Program.

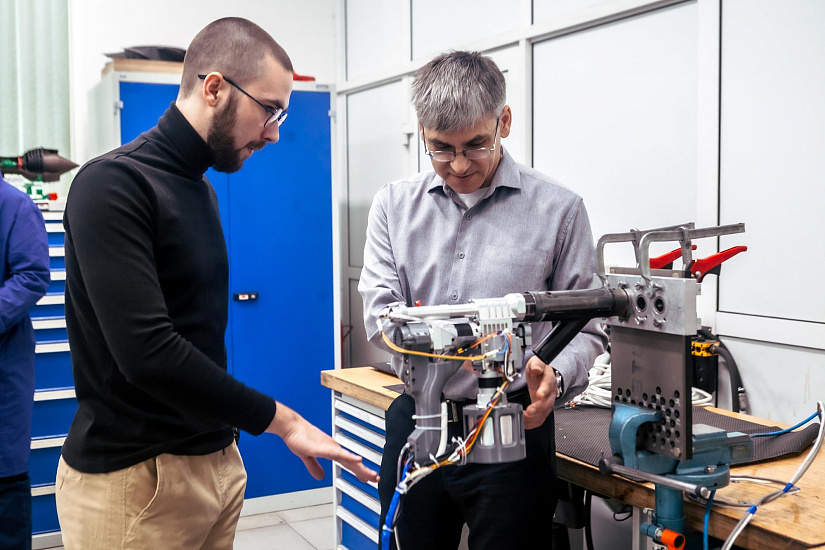

According to Pavel Grishkevich, the head of DTB, the device with separate drill feed and rotation is new to the Russian market. INRTU engineers developed the mechanical part of the drilling machine, installed control and instrumentation systems (CIS) and a cutting fluid supply system (CFSS). The engineers designed and built a working prototype of a tool that can be adjusted to drill holes up to 12 mm in diameter.

"With AFDM, it is possible to drill the required hole in a single setup without changing the cutting tool. This is required to achieve high accuracy when assembling an aircraft. Our device is designed to perform operations in composite steel-titanium-aluminum packages.

The current mission is to redesign the AFDM into something new to meet the needs of the industry, to add elements of modularity to the design for ease of repair and maintenance, and to create a number of modifications. This will be the best offer in terms of production cost as well as tactical and technical characteristics, including weight and dimensions," Pavel Grishkevich emphasized.

The need for a new tool was explained by Dmitry Popov, the Irkutsk Aviation Plant chief engineer for production preparation:

"We expect to receive several modifications of the drilling machine from the university. The plant needs equipment with different designs and process operation characteristics. During the tests we saw that INRTU had made some progress and was ready to improve the prototype to meet the needs of the Irkutsk Aviation Plant".

He also noted that the specific task of Shop No. 46 is to cut holes when joining the fuselage of the MС-21 aircraft, which is why a high-tech tool for processing aluminum packages is required. AFDM will also be used in Shop No. 49 to make holes for the wing and center wing retainer fasteners.

Based on the results of the tests, INRTU and the Irkutsk Aviation Plant developed a plan to finalize the tool, including the creation of protective cases to ensure the impact resistance and durability of the machine, the development of software to regulate drilling parameters – rotation speed, cutting tool feed, thickness of parts, number of layers and holes.

INRTU experts and the plant discussed the possibility of co-financing the development, subsequent modifications, warranty service and methodological support for the Irkutsk Aviation Plant.

Photos by Arseny Chekmaryov