INRTU Develops Automated Sodium Cyanide Analyzer for Gold Extraction

INRTU is developing a system that is to automatically monitor sodium cyanide consumption at gold processing plants. This chemical compound content in processing solutions directly impacts gold recovery rates and wastewater quality. The technical solution, developed under the Priority 2030 Program, will make gold leaching more efficient and minimize environmental risks.

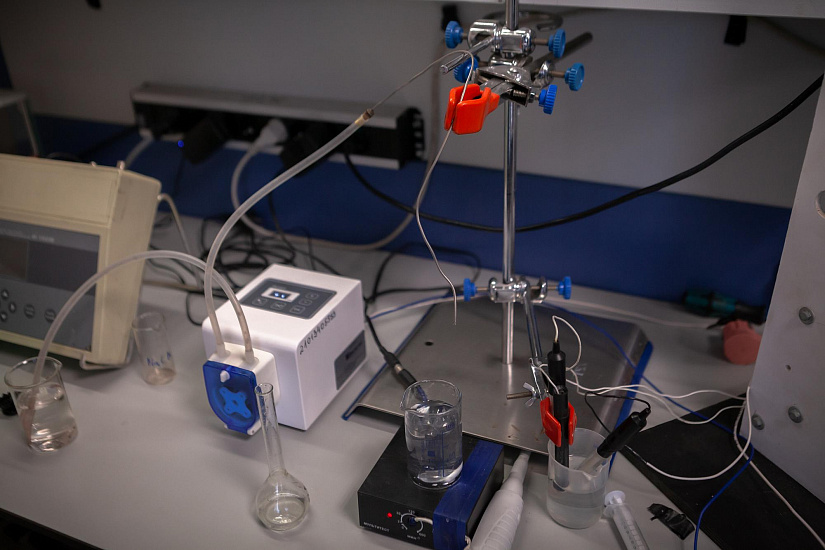

Aleksander Ovsyukov, Associate Professor and scientific supervisor of the Student Scientific and Engineering Center "Automation" (SSEC), explains monitoring the concentration of sodium cyanide is crucial for both technological efficiency and economic viability. Insufficient or excessive amounts of this component equally reduce production quality. This is why mining and processing companies require a system for accurate sodium cyanide concentration measurement. The INRTU students are currently developing such a system based on the principle of potentiometric titration.

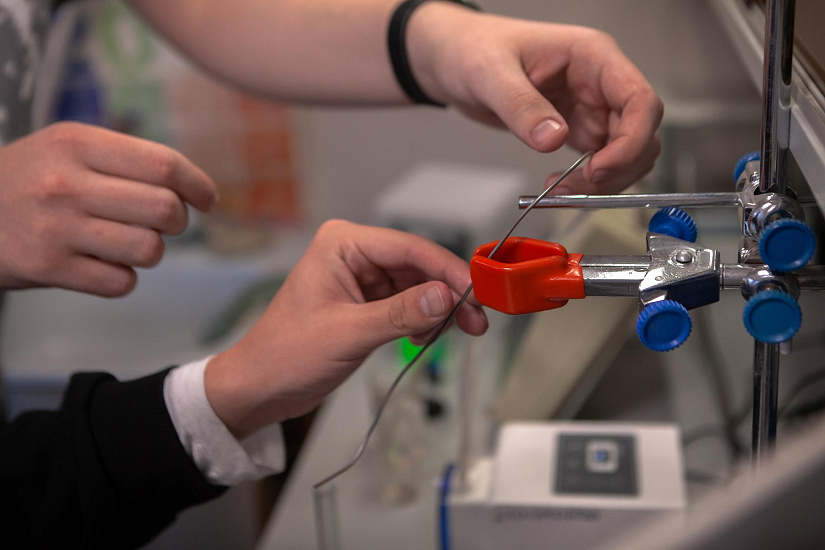

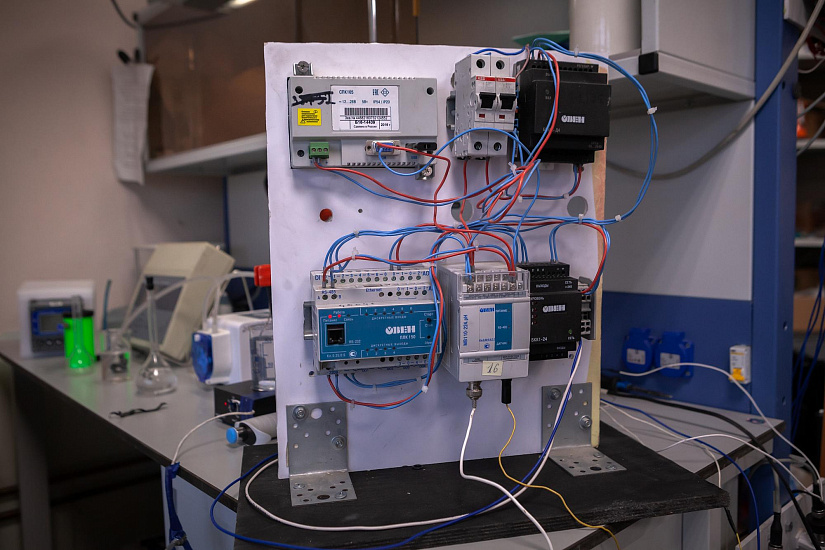

“The measurements rely on monitoring the titration process via the electrode system potential. The resulting titration curve shows the reagent volume consumed in the reaction, which is then used to calculate the component's quantity. Currently, reagent dispensing is manual, but the process of curve generation and reagent consumption calculations are automated. The next step is to develop a fully automated version of the system," says Aleksander Ovsyukov.The team is currently testing the system using pure sodium cyanide solutions. While accuracy of measurements is at a sufficient level, these solutions differ significantly from those used in industrial settings.

"We plan to collaborate with gold mining companies to obtain real-world samples for testing," explained Aleksander Ovsyukov.The ready-to-use device will offer several advantages: low cost, real-time continuous concentration monitoring and transmission of signals to higher-level systems with reporting.

The INRTU Engineering Student Center "Automation" received 200,000 rubles in funding from the university's scientific and technical council for the project. Additionally, the chairman of the association Dmitry Makletsov and activist Artem Rokhmanov won 30,000 rubles in the "Young Inventor" competition and a 100,000 ruble grant as the best student scientific society. These funds will be used to purchase equipment and reagents.

Artem Rokhmanov says participating in the project helps him get immersed in the work of a process automation engineer faster than his peers.

"I'm fascinated to be involved in a gold mining industry project. Dmitry Makletsov and I have learned how to program PLCs, how chemical reagents interact, how electrodes work, and how titration occurs. These are valuable, broadly applicable skills," he noted.The team will present their research at the AS'2024 (Automation Systems) All-Russian Scientific and Practical Conference with international participation, which will be held on 10-12 December 2024 at Siberian State Industrial University in Novokuznetsk.

Photos by Arseny Chekmariov