Design and Technology Bureau of INRTU designs lining replacement devices for mining machines for Intehros Company

The INRTU Design and Technology Bureau which was opened as part of the strategic project i.DIT within Priority 2030 Program, designs the devices which can dismantle the lining (internal coating) in mining equipment. The customer is the Intehros Company, Voronezh, Russia.

The Intehros group of companies has been dealing with engineering and creation of IT-products, electronics, mechanics, hydraulic devices for 24 years. The main production site is located in Voronezh, representative offices are opened in Moscow, Irkutsk, Vladivostok and Riga. The company cooperates with Russian Railways, Gazprom, Polyus, the Ural Mining and Metallurgical Company, Norilsk Nickel and others.

Sergey Konovalyuk, CEO, visited INRTU in spring of 2022. Later, the employees of INRTU Design and Technology Bureau headed by Anton Shutenkov visited the Intehros production site.

According to him, the first significant joint project was the creation of a hydraulic manipulator capable of working in dangerous, inaccessible environments.

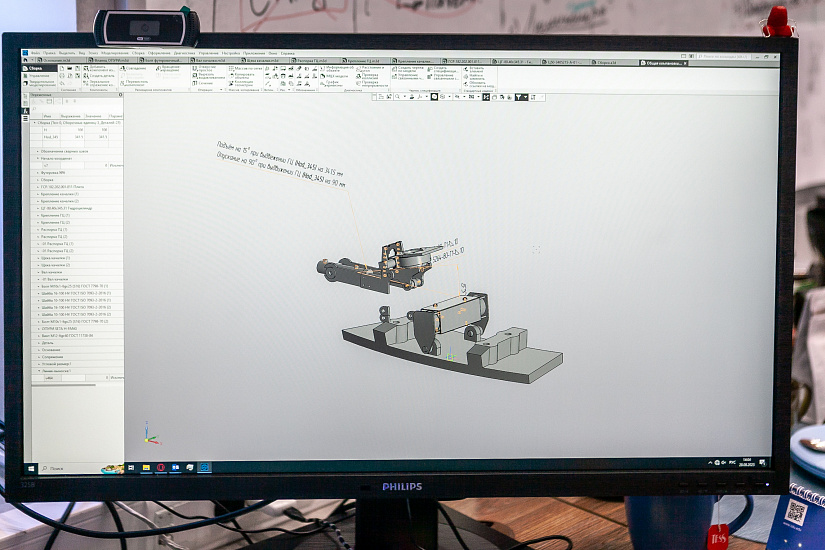

“We designed a robot for the Voronezh company. The main task was to combine a rather large load capacity of 200 kg with the possibility of working in a pipe diameter of 1.3 m. At the moment the industrial trial unit has been manufactured, tested, the results of calculation and design are confirmed. The manipulator can be immersed in radioactive environments for safe dismantling of metal structures,” - said Anton Shutenkov.Now Intehros produces machines to replace the lining in mining equipment, for example, in industrial mills. Lining is internal coating protecting against negative thermal, physico-chemical and mechanical effects. The inventive device is equipped with a telescopic pipe through which worn plates are disassembled from inside. In this project INRTU is engaged in the construction of three tools.

“We are to design mechanisms for removing bolts and lining plates, and also a removable loading device, as there are different types of lining. It is important to provide a load capacity of two tons with a safety margin of 25%. Dimensions are still discussed with the customer,” - said Anton Shutenkov.The team also includes Alexander Valeyev, who specializes in design, and Andrei Duk, who is responsible for calculations.

“At the moment we are dealing with development of the overall concept, selection of components. After preparing drawings and design documentation, we will send the project to the Intehros for approval,” - said engineer researcher Alexander Valeyev.In November INRTU Design and Technology Bureau is going to work on a new robot for Intehros.

Photos by Arseny Chekmarev